Clinker or Vitrified: Which is the Best Tile for Me?

Why Tile Type Matters

Not all tiles are created equal. The performance of your floor depends heavily on the type of tile you choose. In industrial and commercial environments, strength, density, and resistance to water and chemicals are critical. Two terms you may hear in specifications are clinker tile and fully vitrified tile. While they are sometimes used interchangeably, they are not the same — and the differences matter.

What is the difference between vitrified and ceramic tiles?

It comes down to composition. Both kinds of tile are made from clay, but vitrified tile also includes elements that melt at high temperatures, much like glass. This makes the finished tile harder, denser, stronger and less porous than purely ceramic tile.

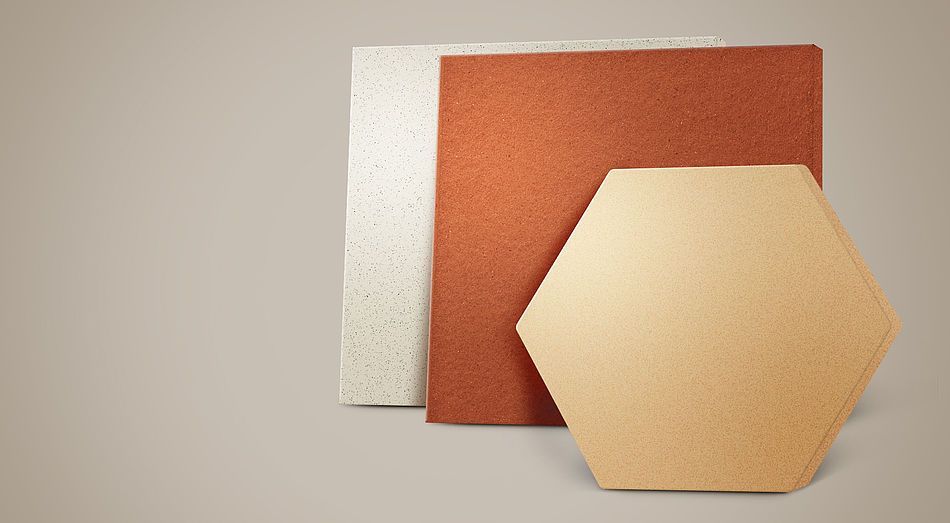

WHAT IS FULLY VITRIFIED TILE?

Fully vitrified ceramic tiles are manufactured using a blend of natural clay, quartz, and silica. During firing, these elements melt together at extremely high temperatures, forming a dense, glass-like structure. The result is a tile that is:

- Exceptionally strong and durable

- Virtually waterproof (absorption rate < 0.1%)

- Resistant to chemicals, frost, and heavy loads

- Consistent in color and composition throughout (full-body tile)

Because the color runs through the entire tile, scratches or chips are far less visible, and performance is unaffected. These properties make vitrified tiles the gold standard for demanding environments like automotive workshops, food processing plants, and breweries.

Why People Still Say “Clinker Tile”

In some markets — especially in the U.S. — the word clinker has become a generic way to describe dense industrial tile. When architects or engineers specify “clinker tile,” they are usually referring to fully vitrified tile.

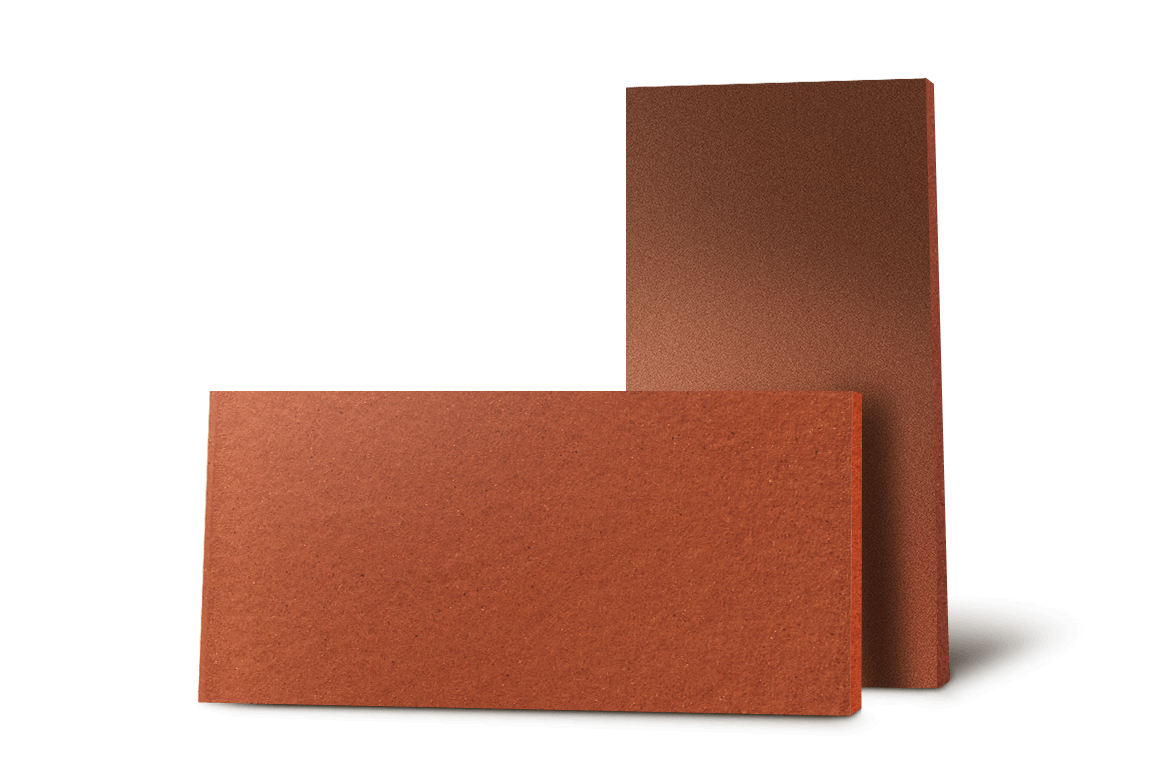

Historically, red clinker tiles were produced in Europe as a partially vitrified alternative to glazed ceramic tile. They were stronger than standard ceramics, but with an absorption rate of 2–4%, they required maintenance such as periodic oiling to improve resistance.

Today, however, clinker is considered an outdated product. For projects where durability and hygiene are non-negotiable, fully vitrified tiles have completely replaced clinker.

Why Argelith Focuses Exclusively on Vitrified Tile

At Argelith, we no longer manufacture clinker tiles. Our entire production is dedicated to fully vitrified industrial tiles, because they consistently outperform clinker in strength, water resistance, and long-term performance.

By focusing only on vitrified tiles, we ensure that every floor we supply is built for maximum durability, safety, and value.

IS TILE A GOOD CHOICE FOR MY FACILITY?

Industrial tile is an excellent choice for many, but not all, industrial and commercial facilities. Connect with one of our knowledgeable account managers to learn if tile is the right choice for you.