Industrial Tiles

for Brewery Flooring

Whether rectangular, square, hexagonal or a ceramic molding – Argelith offers a wide range of shapes, colors and surfaces in the porcelain stoneware sector. Further details can be found in the following product descriptions.

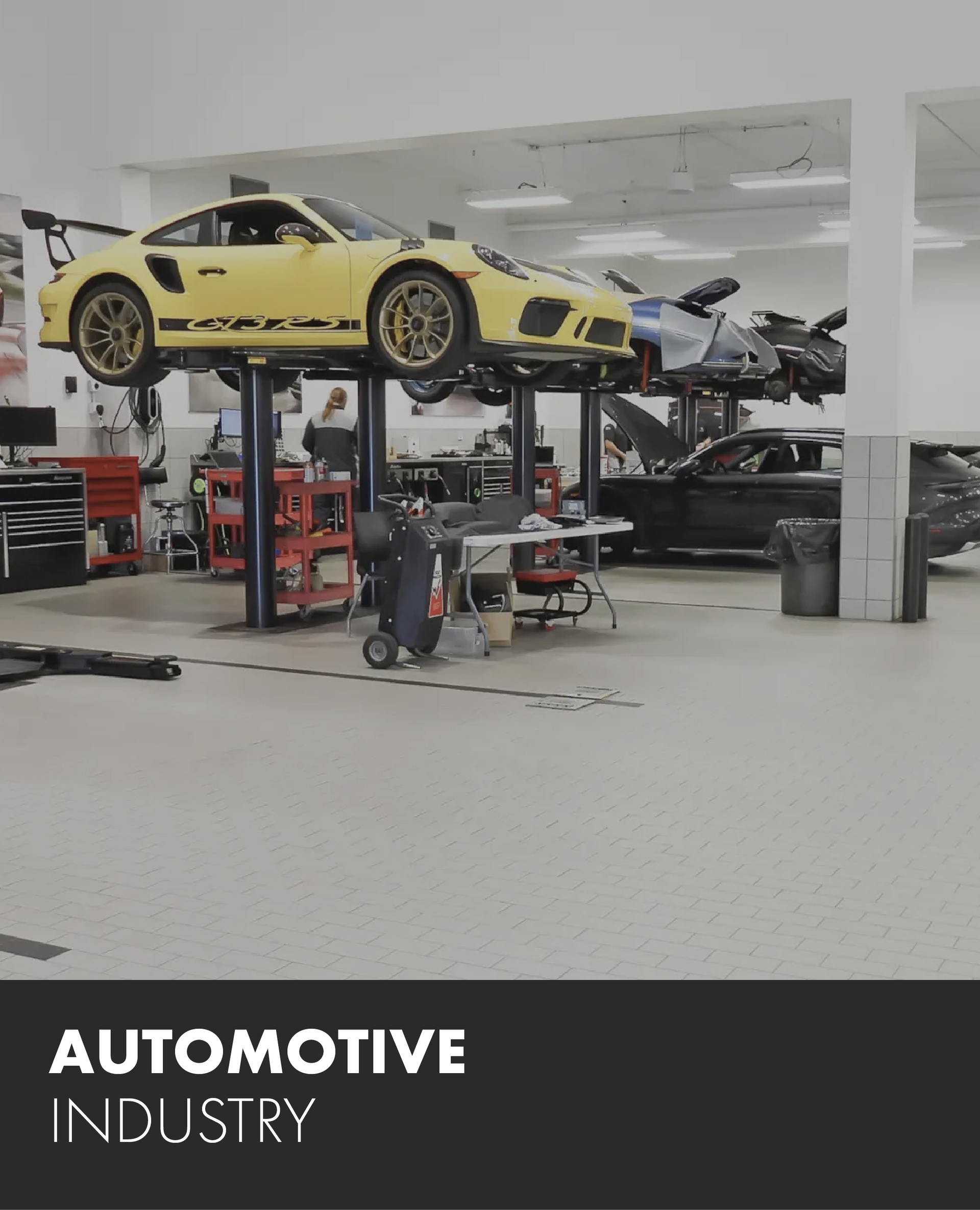

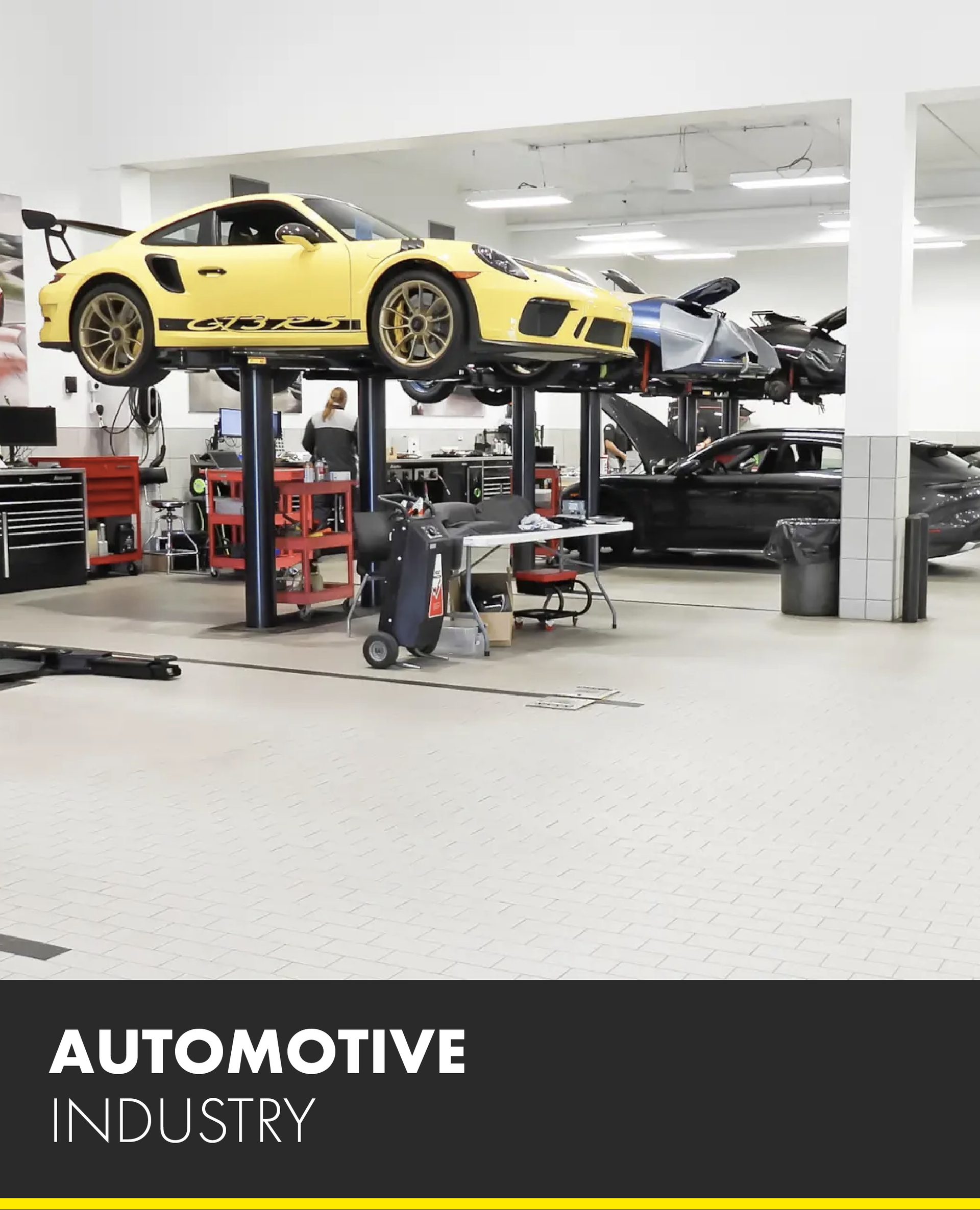

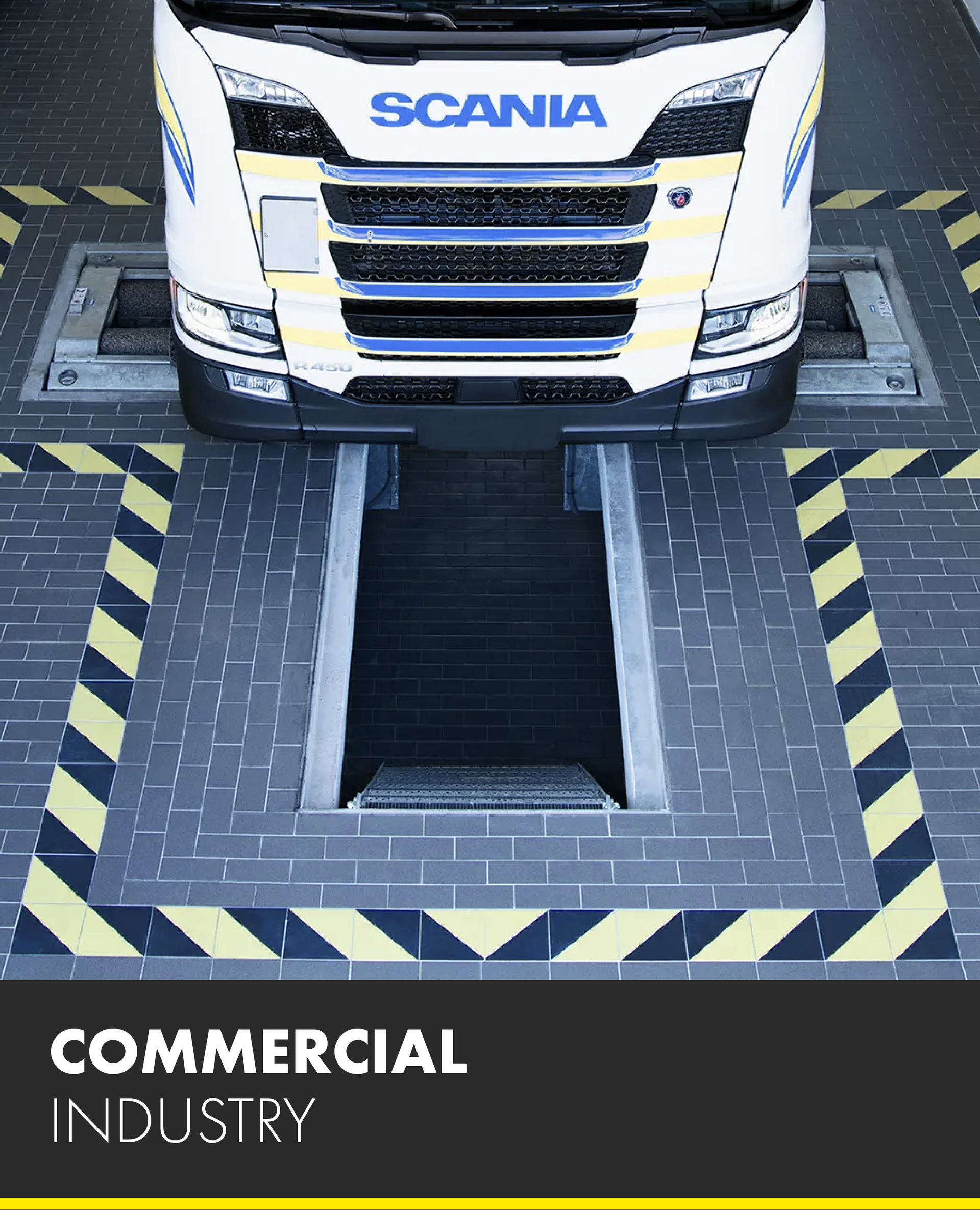

From the food industry to vehicle workshops, laboratories, chemical plants, and airplane hangars, each sector demands heavy-duty floor coverings that can meet varying requirements for slip resistance, hygiene, and load-bearing capacity. Argelith specializes in these specific applications, offering robust industrial flooring solutions with extra-strong tiles ranging from 3/8 to 3/4 inch in thickness. Our expertise ensures you have the ideal foundation for any challenging environment.

benefits for

BREWERIES, WINERIES, AND OTHER BEVERAGE PRODUCERS

- High Density - superior resistance to moisture & liquids

- VERY HARD-WEARING

- COMPLIES WITH ALL STATUTORY HYGIENE STANDARDS

- DESIGNED FOR EASY, COST-EFFECTIVE CLEANING

Your Solution Starts Here

Every industry is unique—so are your needs

Request a sample to see the Argelith difference or consult with our specialists to find the best solution for your space.

Challenges in

Brewery Flooring

Your brewery's flooring goes through a lot. Heat, cold, spills, and heavy traffic are part of everyday operations. Installing the wrong flooring can lead to cracks, slippery surfaces, or sanitation problems. Choosing the right material helps keep workers safe, equipment moving, and cleanup simple.

Slip Hazards

Wet floors are unavoidable in brewing environments. Spills from ingredients, condensation, and routine washdowns create persistent slip risks, especially in high-traffic zones like bottling lines and fermentation rooms. Argelith tiles are engineered with a non-skid surface that meets or exceeds industry standards for slip resistance, even when wet. This helps protect workers while maintaining the efficiency of operations.

Thermal Shock

The drastic temperature changes in a brewery, from boiling kettles to cold storage, can cause lesser flooring materials to crack or delaminate. Argelith’s fully vitrified tiles are thermally stable and designed to endure these shocks without compromising structural integrity. While our fully vitrified tiles still experience thermal expansion and contraction, their dense structure ensures this movement occurs at a significantly reduced rate compared to other materials, minimizing the risk of long-term damage.

High Foot Traffic

Brewery floors endure constant movement, from foot traffic to forklifts and heavy carts. Without the right flooring solution, surfaces can wear unevenly or develop safety hazards. Argelith tiles are pressed and fired for extreme density and hardness, making them resistant to abrasion even in the most demanding environments. Their performance remains consistent over time, ensuring your brewery maintains both safety and aesthetics.

How Argelith Ceramic Tiles Benefit Breweries

Brewery operations require flooring solutions that perform under constant stress, from extreme temperatures and acidic ingredients to relentless foot and cart traffic. Argelith Ceramic Tiles are engineered to deliver superior performance in every phase of the brewing process.

With a fully vitrified structure, these tiles repel moisture, resist chemical damage from cleaning agents and spilled beer, and hold up against thermal shock from brewing cycles. Their high load-bearing capacity allows them to endure the weight of kegs, tanks, and forklifts without cracking or chipping. Beyond durability, Argelith tiles support hygiene compliance: smooth, sealed surfaces prevent the absorption of liquids and bacteria, promoting sanitary conditions essential for food and beverage production. Available in formats that support effective drainage and slope, Argelith tiles help breweries reduce downtime and maintain a clean, safe environment with minimal effort.

Maintenance Tips to Ensure Your Floor Lasts

To maximize the lifespan and performance of your Argelith brewery floor, proper maintenance is essential. Begin with installation: ensure that experienced installers use narrow grout joints (1/16" to 1/8") to reduce water pooling and edge chipping. Based on chemical exposure, we may recommend epoxy grout due to its superior chemical resistance. However, in zones with extreme chemical exposure, such as around Clean-in-Place (CIP) systems, a vinyl ester grout may be required for optimal durability. To ensure the best performance, we recommend providing a list of chemicals used in your facility so we can assist in selecting the most appropriate grout solution for your environment.

After installation, a thorough wash will remove grout haze and prepare the tiles for long-term use. Regular cleaning with an auto-scrubber, equipped with suitable pads, including aggressive options for tough grime will keep the surface free of residue without damaging the tile. By combining

expert installation with disciplined maintenance, breweries can rely on Argelith floors to deliver lasting performance, safety, and visual integrity.

Note: Slip resistance depends on proper cleaning, footwear, maintenance, and environmental factors. While Argelith tiles feature engineered textures, no flooring system can eliminate all risk of slips or falls.

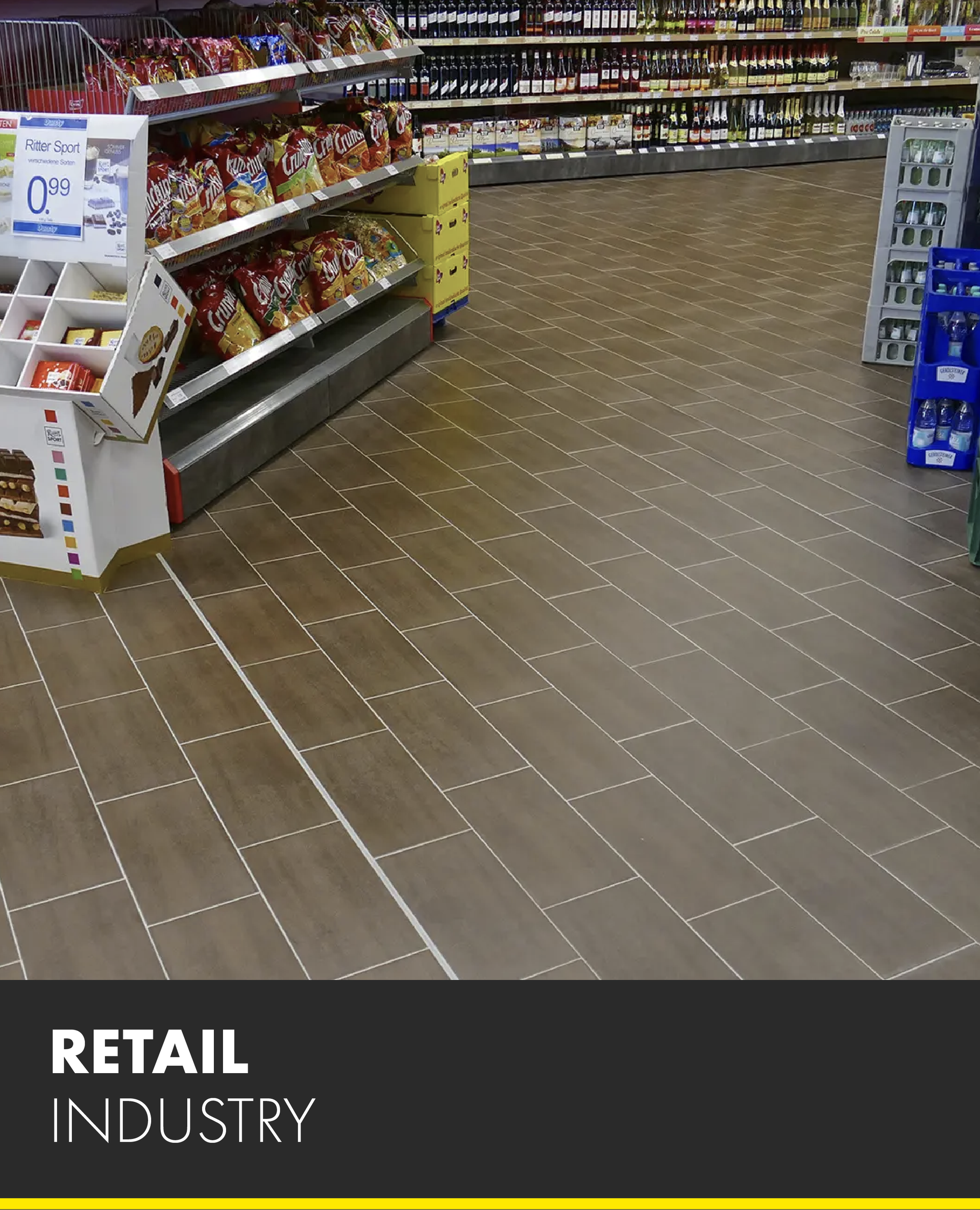

application areas

argelith tiles

Nothing Yet?

choose your favorite product from our diverse collection

Beverage production and bottling plants require one thing above all else: a hard-wearing floor that is both hygienic and safe. Argelith ceramic floors fulfil all three requirements. They are easy to clean and resistant to chemicals, are supplied in an impressive thickness for withstanding heavy loads, and come equipped with “smart” surface contours designed to ensure a good grip even when wet. Their extremely high density ensures that no moisture can penetrate the surface. This makes them the perfect floor covering for any kind of bottling facility; be it a brewery, winery, mineral-water or soft-drink plant.