Workshop floors face relentless challenges—from oil and grease to alkaline and acid spills, not to mention the stress from heavy vehicles and the impact of dropped tools. For such demanding environments, an extra-strong, easy-to-clean ceramic tile is essential. Argelith has been specializing in ceramic tiles that meet these rigorous demands for decades. Leading car manufacturers trust and specify our tiles in their construction guidelines, recognizing the unmatched durability and performance Argelith provides.

Engineered Flooring for Every Automotive Zone

From dealership service departments to independent repair shops and high-performance garages, automotive facilities demand flooring that withstands heavy vehicles, chemical exposure, and constant cleaning. Argelith fully vitrified ceramic tiles are engineered to perform in service bays, workshops, wash areas, and parts departments—delivering slip resistance, structural strength, and long-term durability in high-intensity automotive environments.

Service Bays

Our fully vitrified tiles come in traditional square shapes. These slip-resistant floors provide a safe surface and a classic look to suit many businesses.

Workshop Areas

Ideal for automotive workshops and performance garages, these anti-slip tiles resist fuel, coolants, and abrasion from daily vehicle movement and equipment use.

Wash Bays

Designed for car wash and detailing bays, Argelith tiles handle constant water exposure, detergents, and chemical cleaners while maintaining reliable traction in wet conditions.

Parts & Prep Areas

In parts rooms and vehicle prep zones, Argelith flooring resists impact, staining, and rolling cart traffic while maintaining a clean, professional appearance.

Your Solution Starts Here

Every industry is unique—so are your needs

Request a sample to see the Argelith difference or consult with our specialists to find the best solution for your space.

Challenges in Automotive Flooring

Modern automotive environments are complex and high-intensity, placing immense stress on flooring materials. From mechanical servicing areas to vehicle showrooms, these spaces face a unique combination of chemical exposure, mechanical load, and rigorous cleaning protocols. Argelith engineered tiles are specifically designed to withstand these challenges while maintaining performance and visual integrity over time.

Exposure to Automotive Fluids

Shops frequently encounter motor oil, brake fluid, coolant, and other aggressive substances. These liquids can stain, degrade, or penetrate lesser flooring surfaces, compromising appearance and hygiene. Argelith tiles feature a fully vitrified structure with an ultra-low absorption rate that prevents seepage and resists chemical damage.

Heavy Equipment

Vehicle lifts, rolling tool chests, and tire racks impose significant point loads that can crack or wear conventional flooring. Argelith tiles are engineered with exceptional compressive strength, making them ideal for high-impact areas. Argelith tiles are dry pressed and the edges have built in spacers.

Frequent Cleaning

Cleanliness is essential in both operational and customer-facing areas. Argelith’s dense surface resists staining and is compatible with scrubbers, degreasers, and industrial cleaning agents. Whether dealing with daily grime or deep-cleaning with acid solutions, Argelith tiles retain their appearance without sacrificing performance.

How Argelith Ceramic Tiles Benefit Auto Spaces

Automotive environments demand flooring that performs under pressure. Argelith ceramic tiles are built for this challenge, combining strength, safety, and cleanability in a durable, engineered solution.

Load Resistance: Withstand vehicles and equipment without cracking.

Chemical Defense: Resist oils, solvents, and harsh cleaners.

Slip Control:

Textured surfaces help reduce accidents,

even when wet.

Low Maintenance: Easy to clean with auto-scrubbers and aggressive pads.

Lasting Aesthetics: Retain finish and color under constant use, ideal for automotive shops and service areas.

Industrial Tiles for Auto Dealerships & Workshops

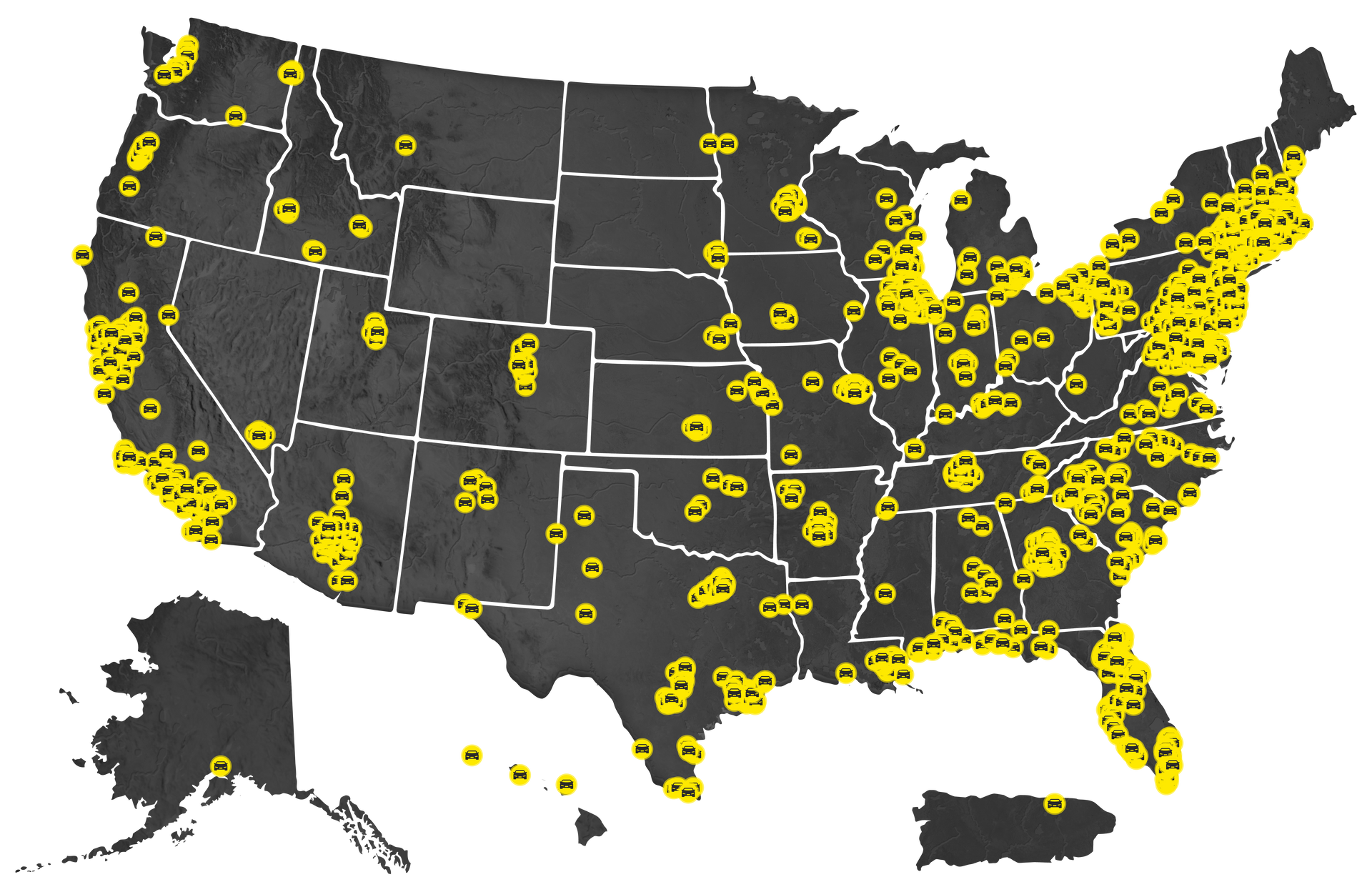

Serving Dealerships across the United States

Over 1800 Locations

Nothing Yet?

choose your favorite product from our diverse collection

Whether rectangular, square, hexagonal or accessory tiles – Argelith offers a wide range of shapes, colors and surfaces in the porcelain stoneware sector. Further details can be found in the following product descriptions.

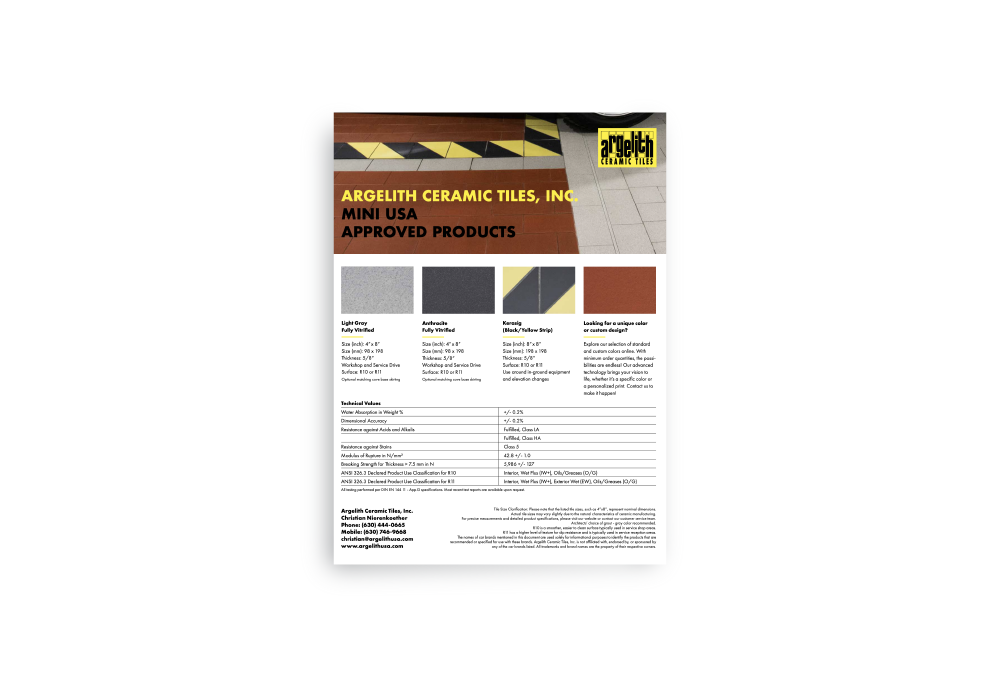

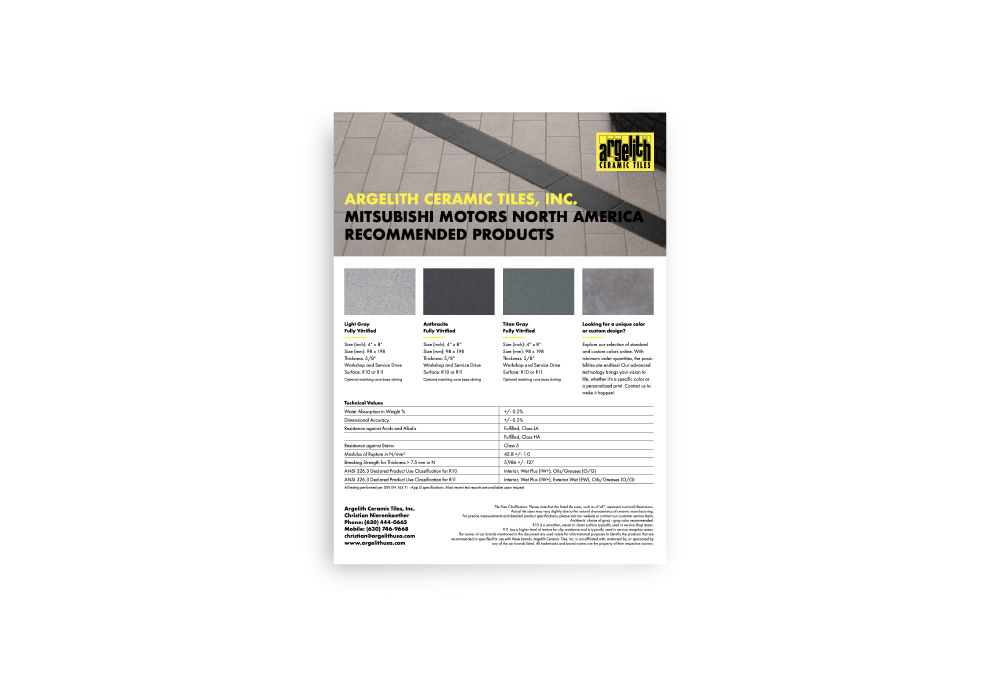

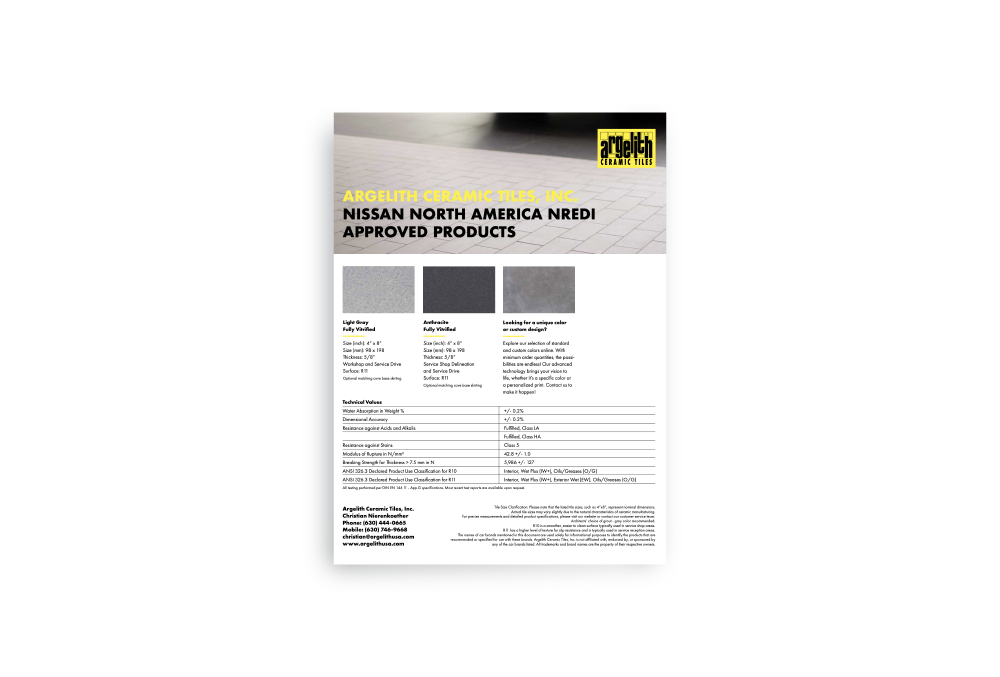

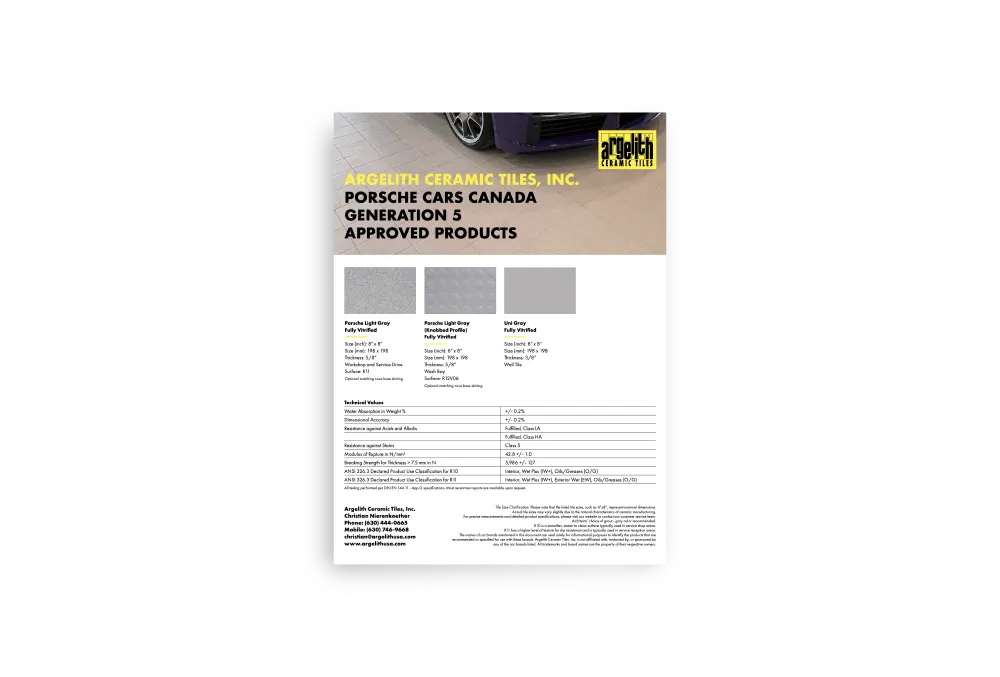

The Choice of industry leaders

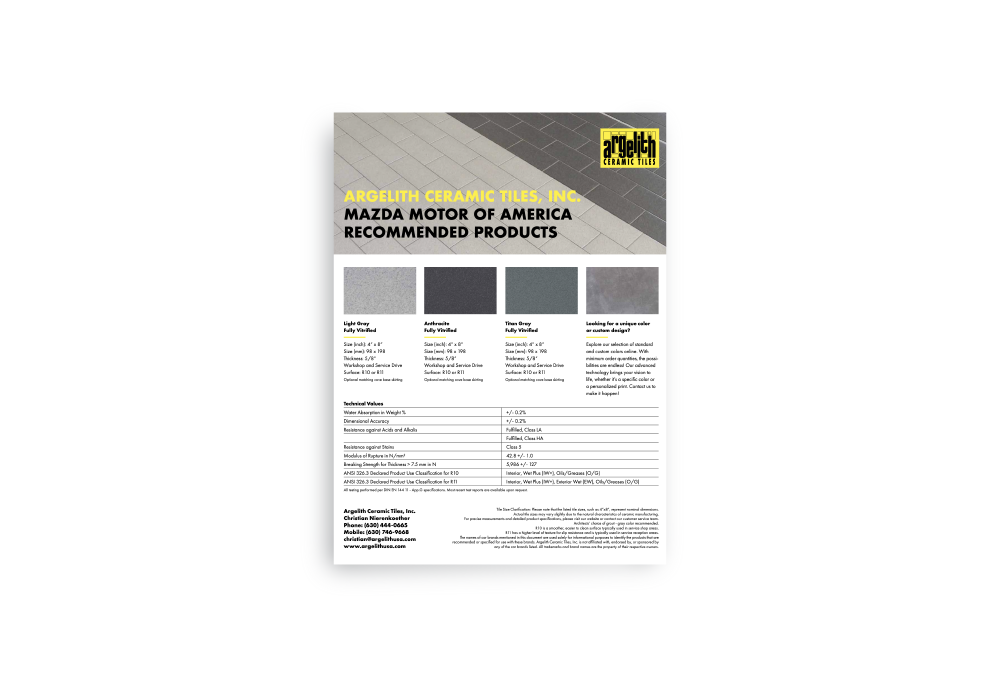

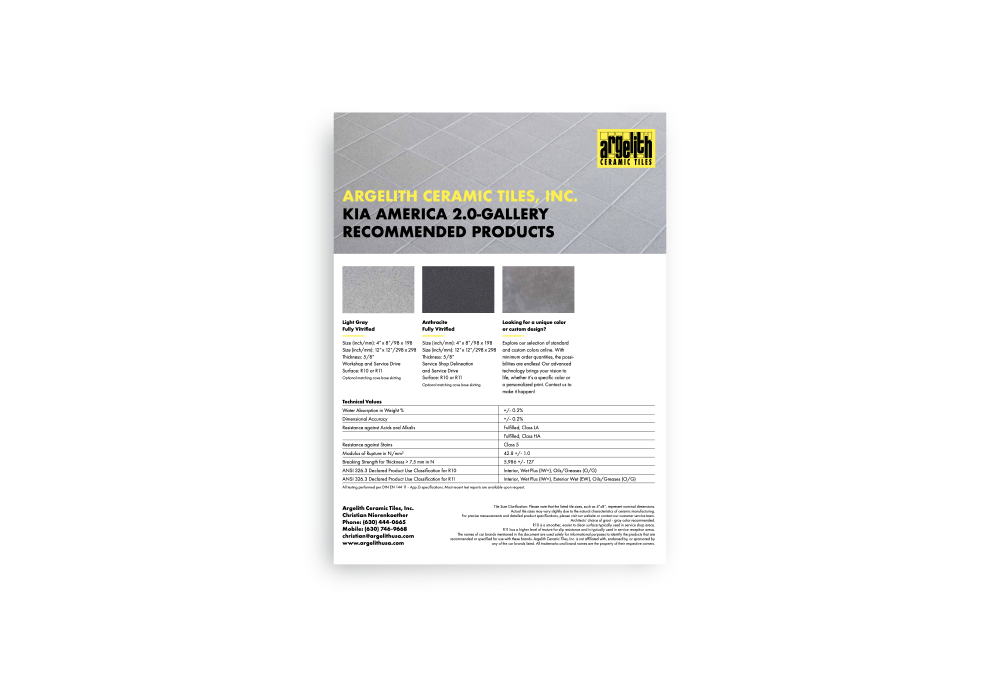

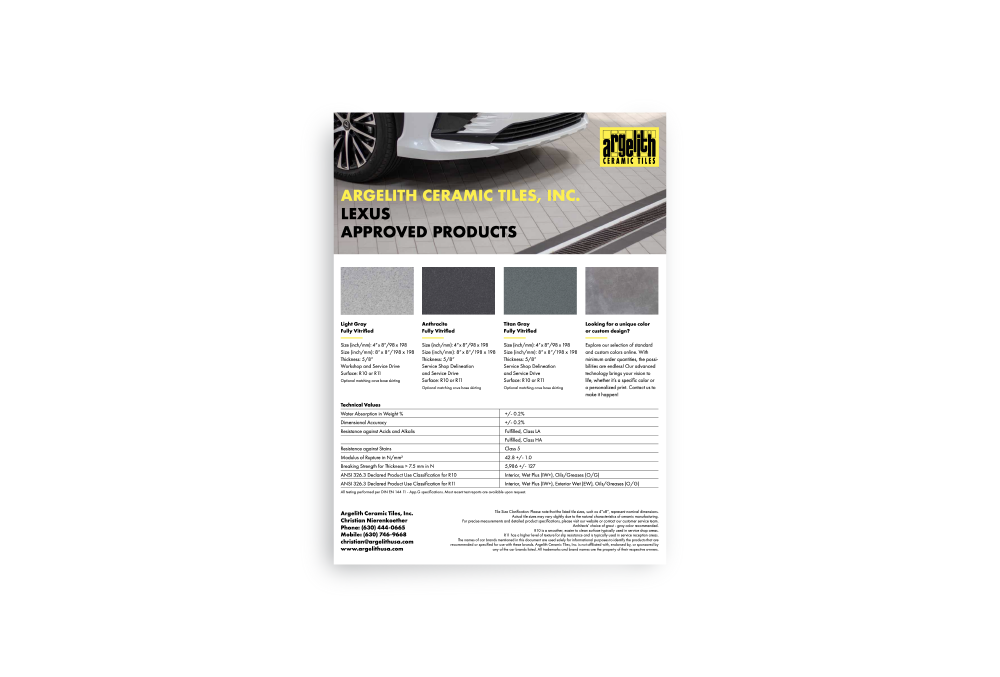

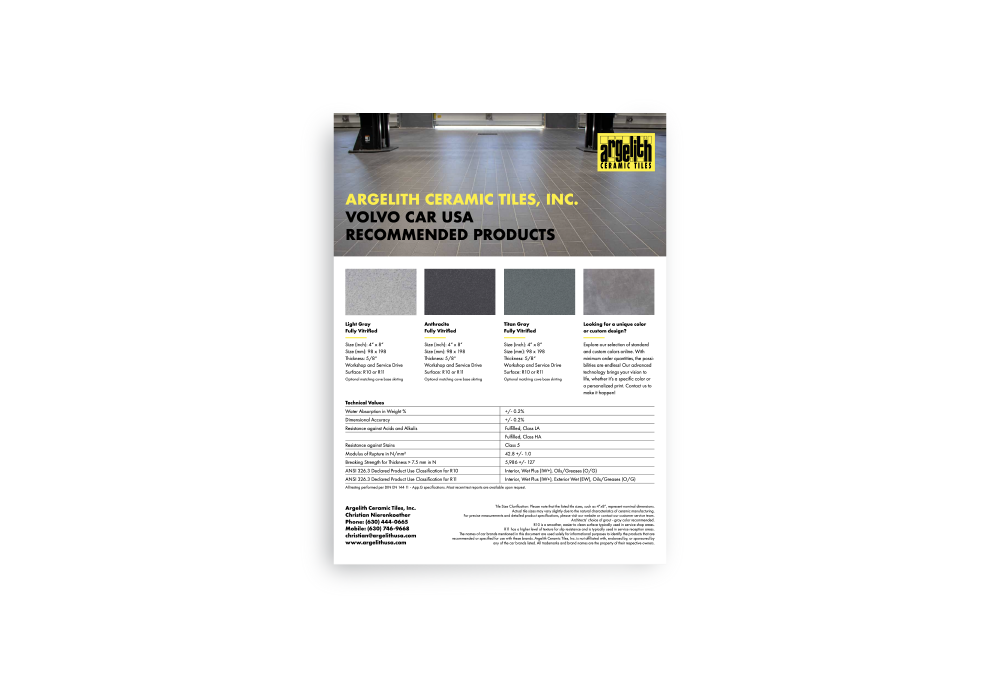

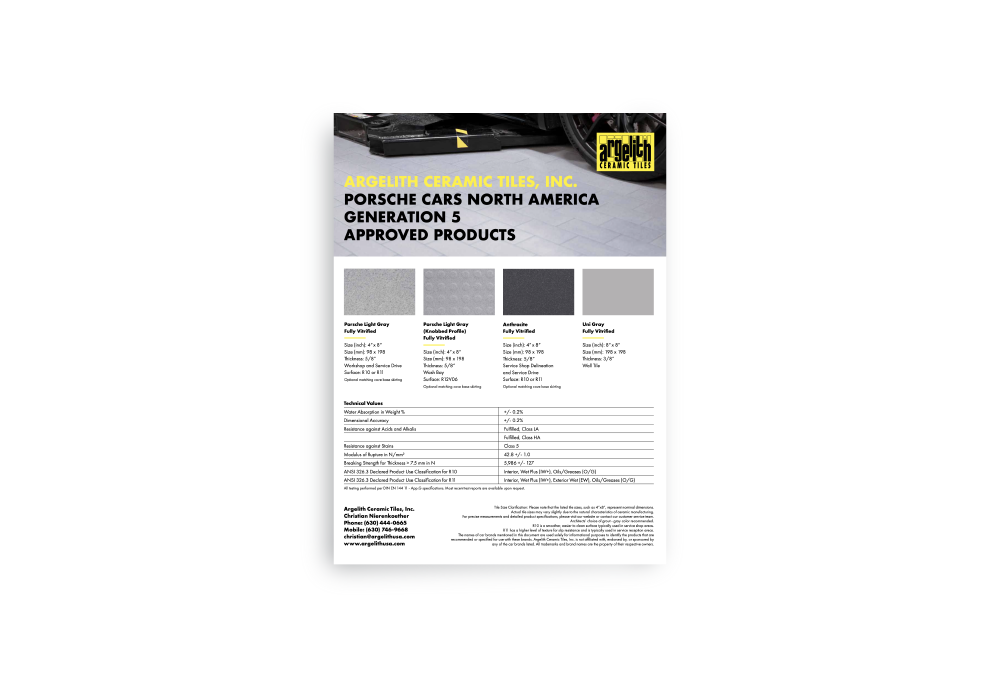

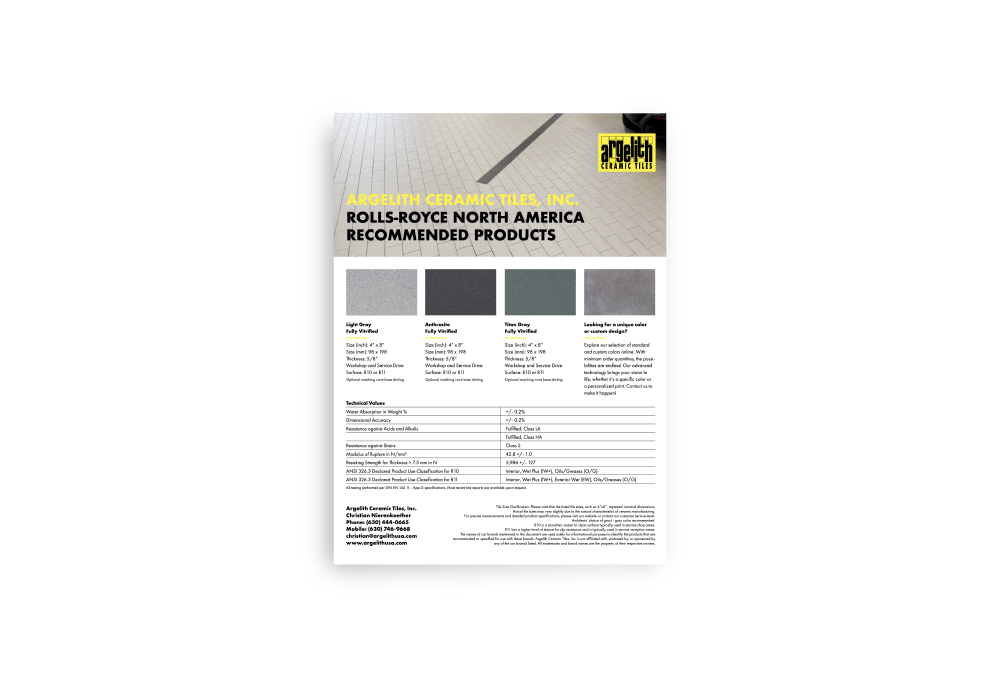

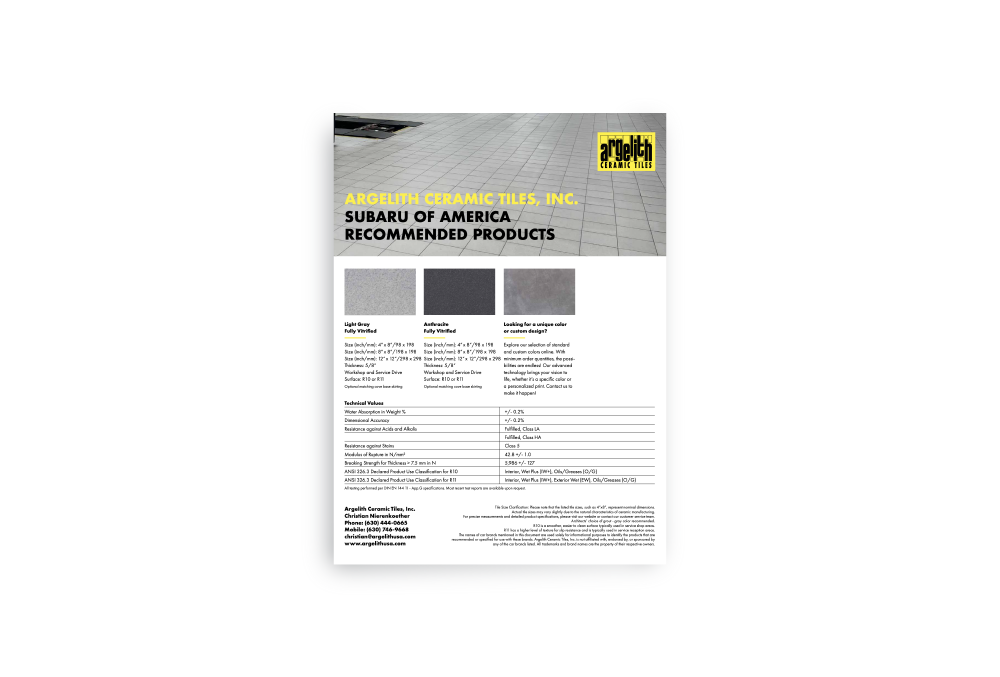

brand sheets

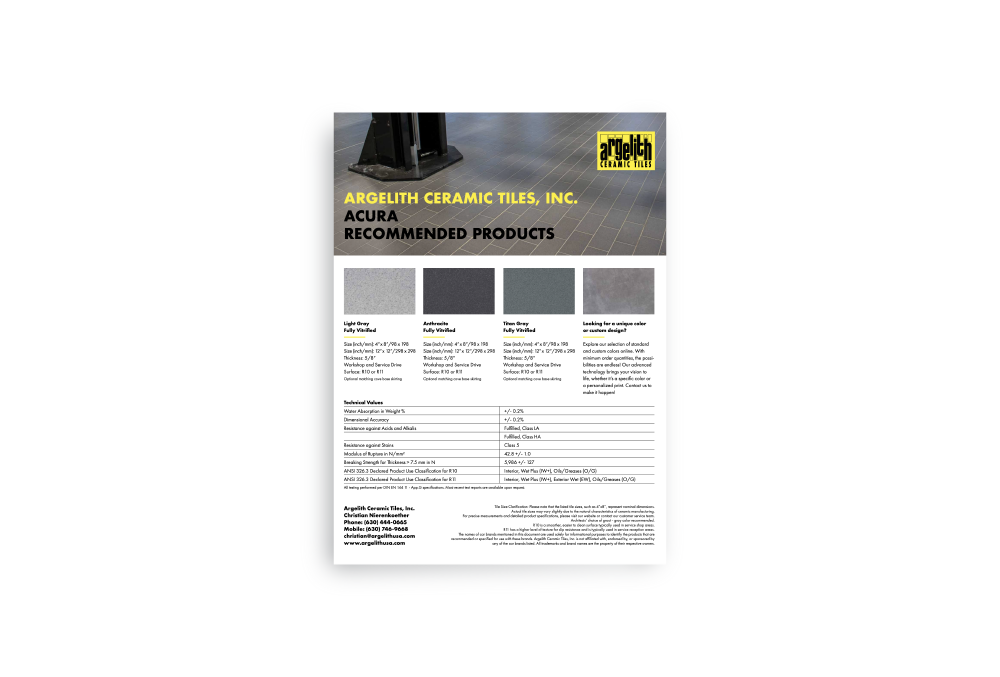

Acura

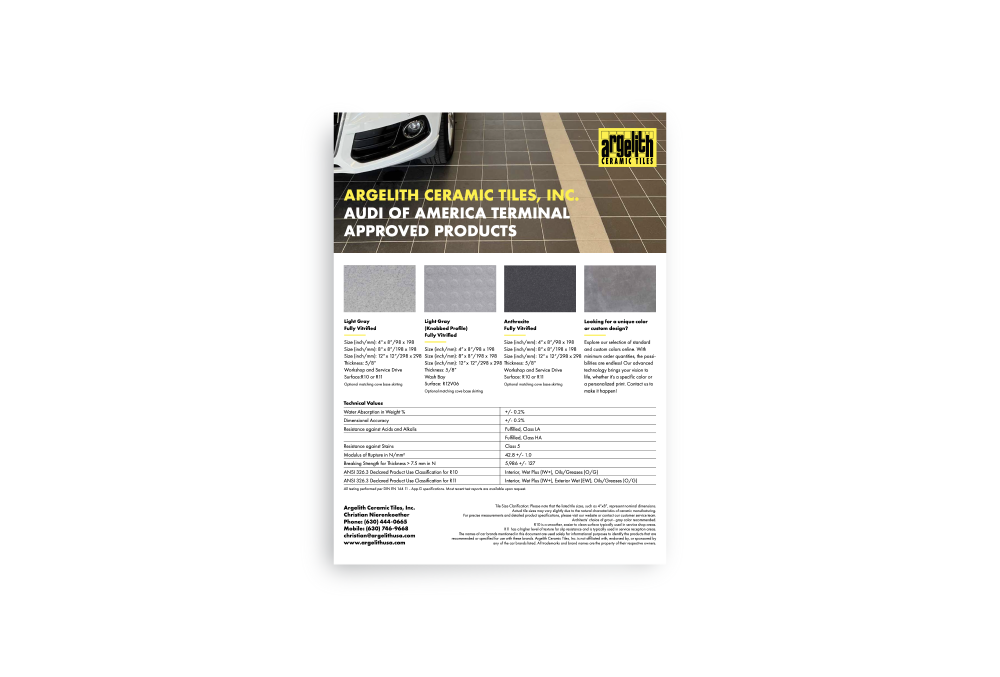

AUDI of america

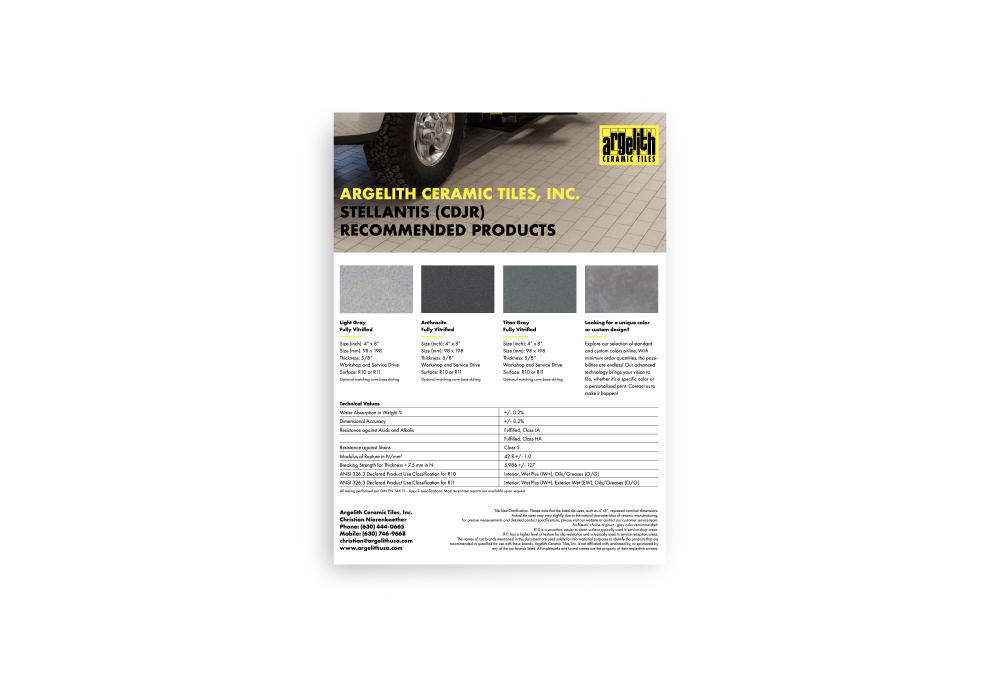

stellantis (CDJR)

maserati usa

honda motor co.

jaguar land rover north america

kia america

lexus

toyota motor north america

volvo car usa

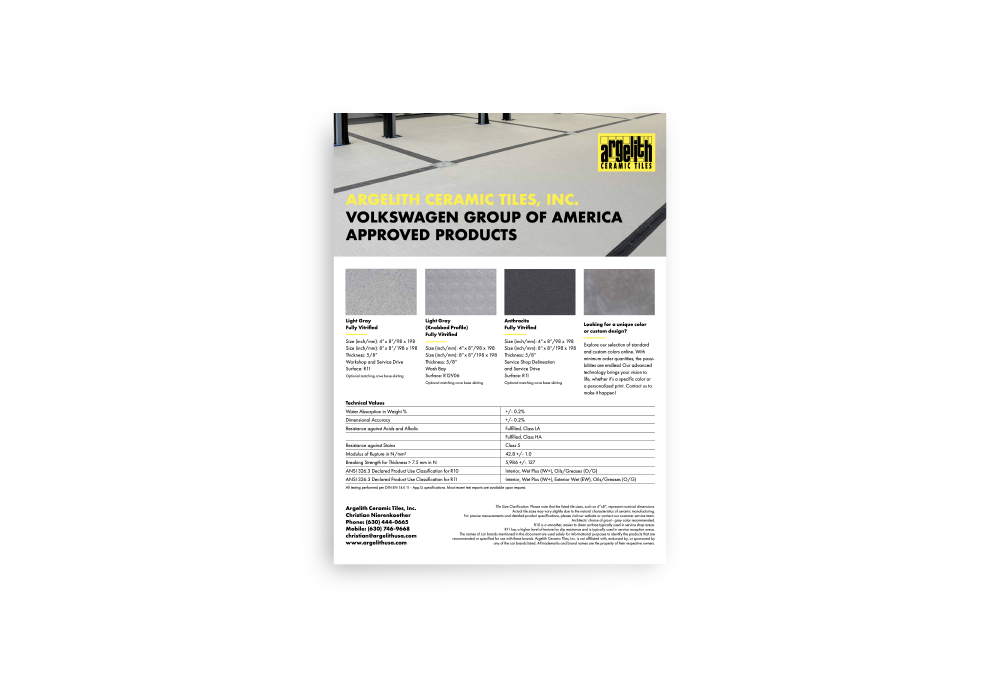

volkswagen group of america

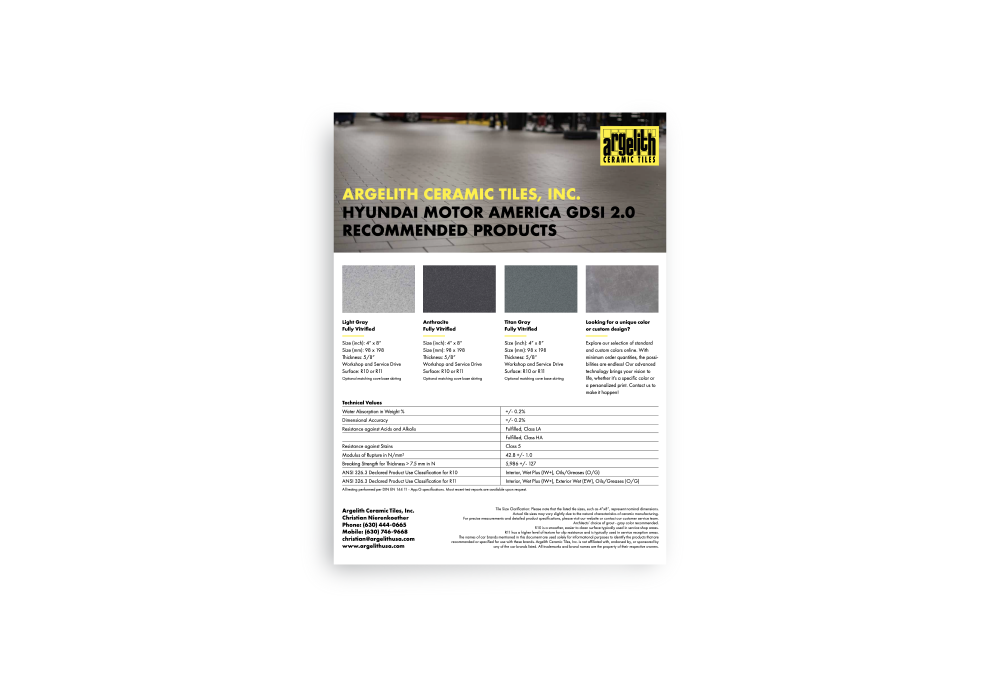

hyundai motor america

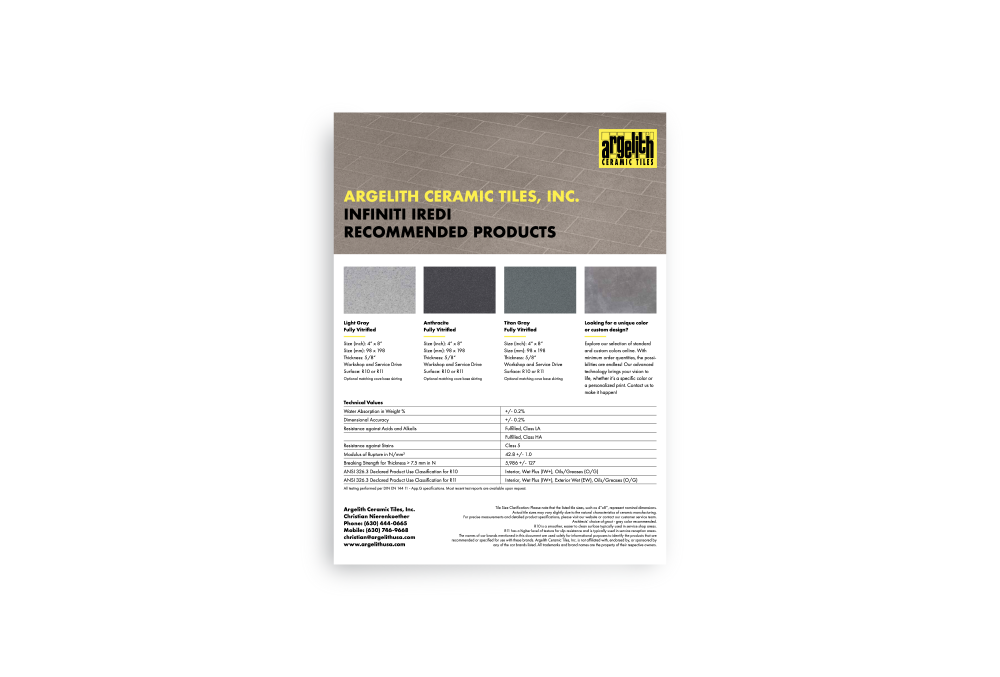

infiniti

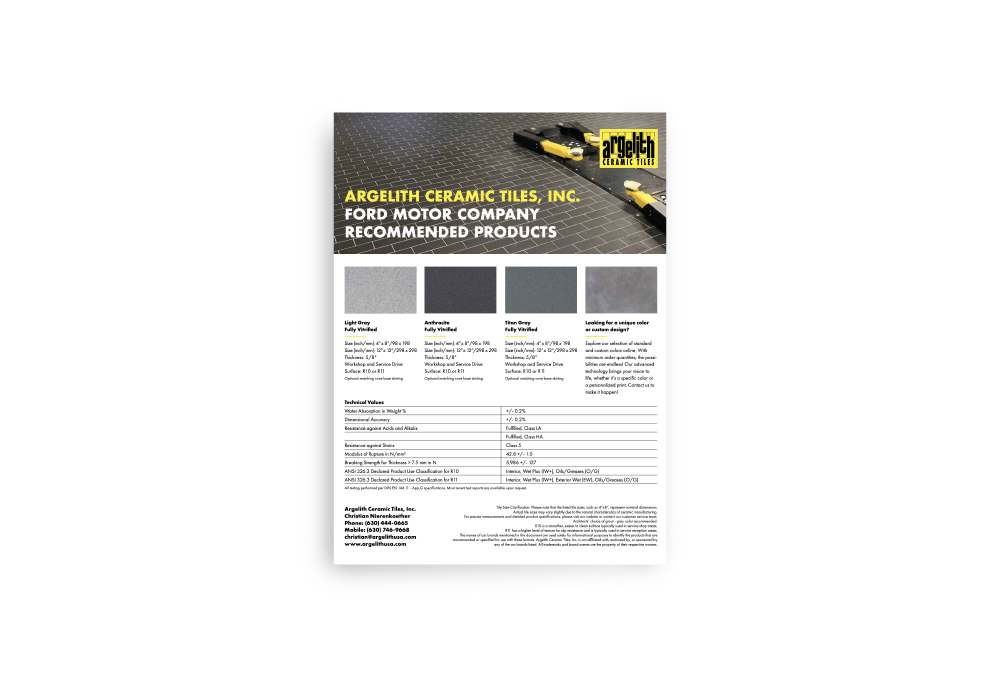

ford motor company

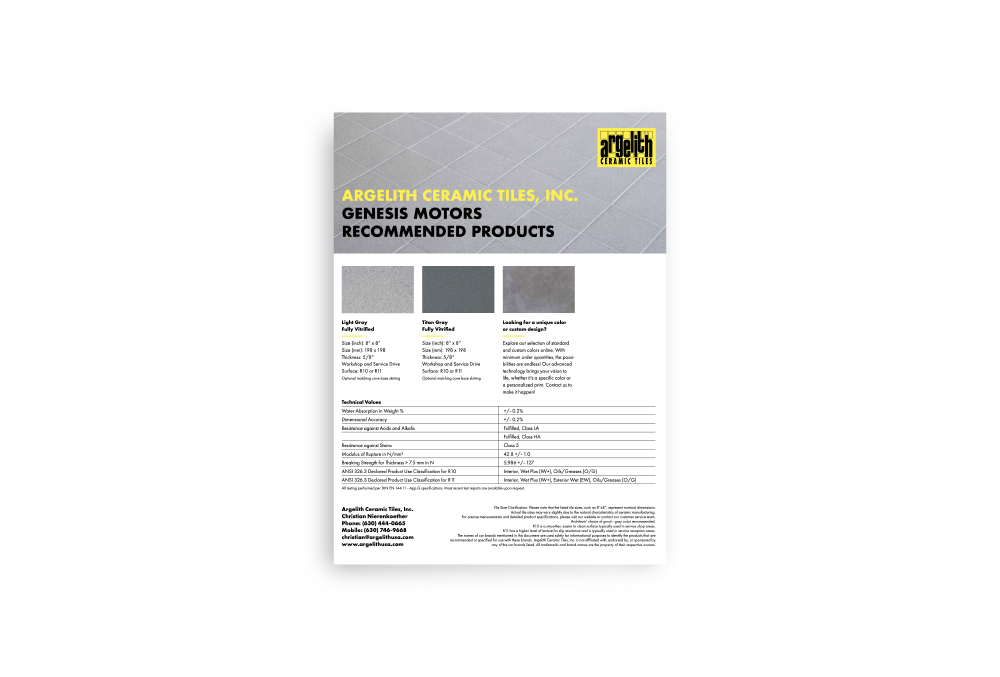

genesis motors

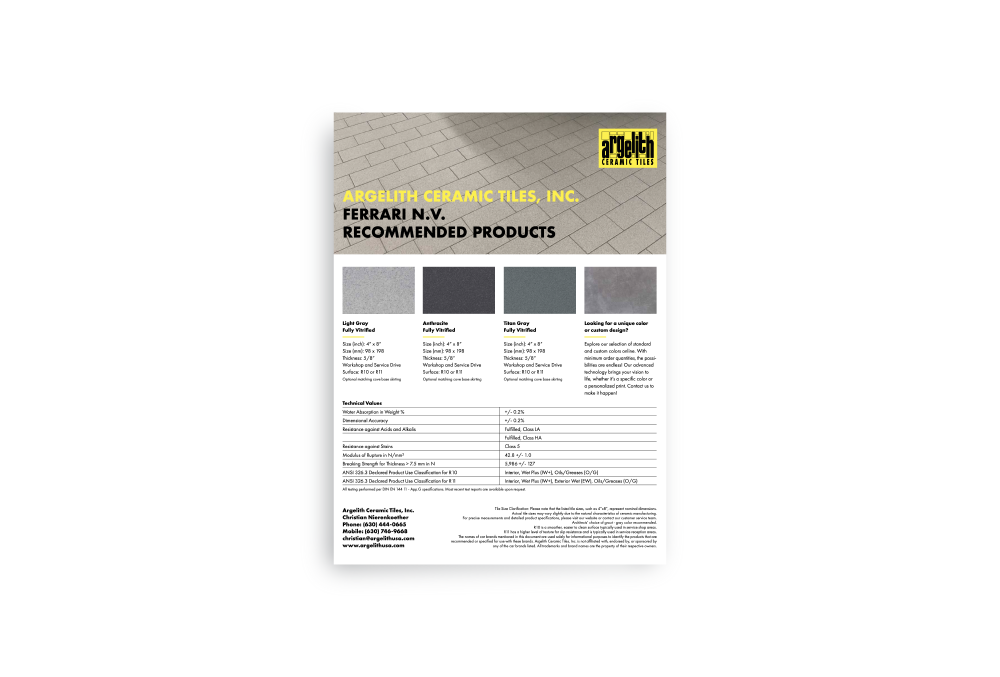

FERRARI n.v.

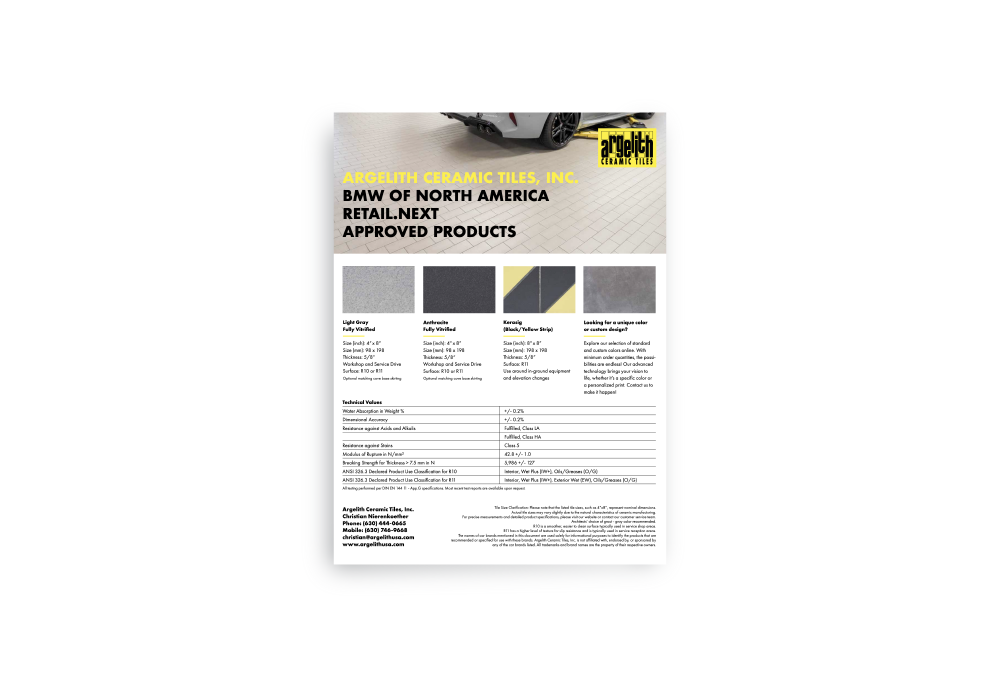

BMW of north america

mazda motor of america

mitsubishi motors north america

nissan north america

porsche cars canada

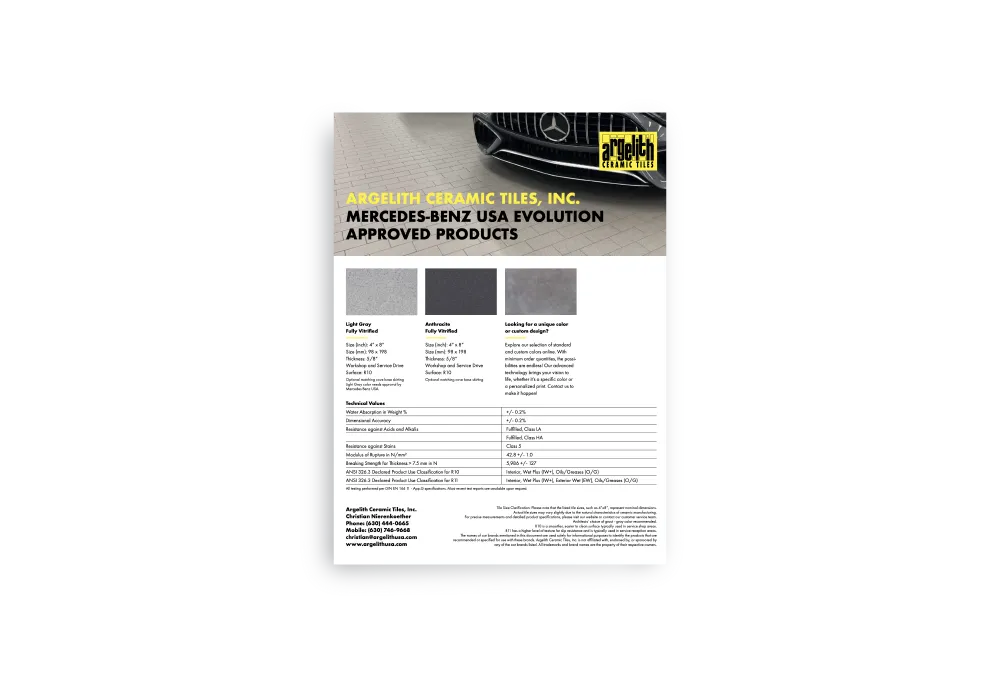

mercedes-benz usa

mini usa

porsche cars north america

rolls-royce north america

subaru of america

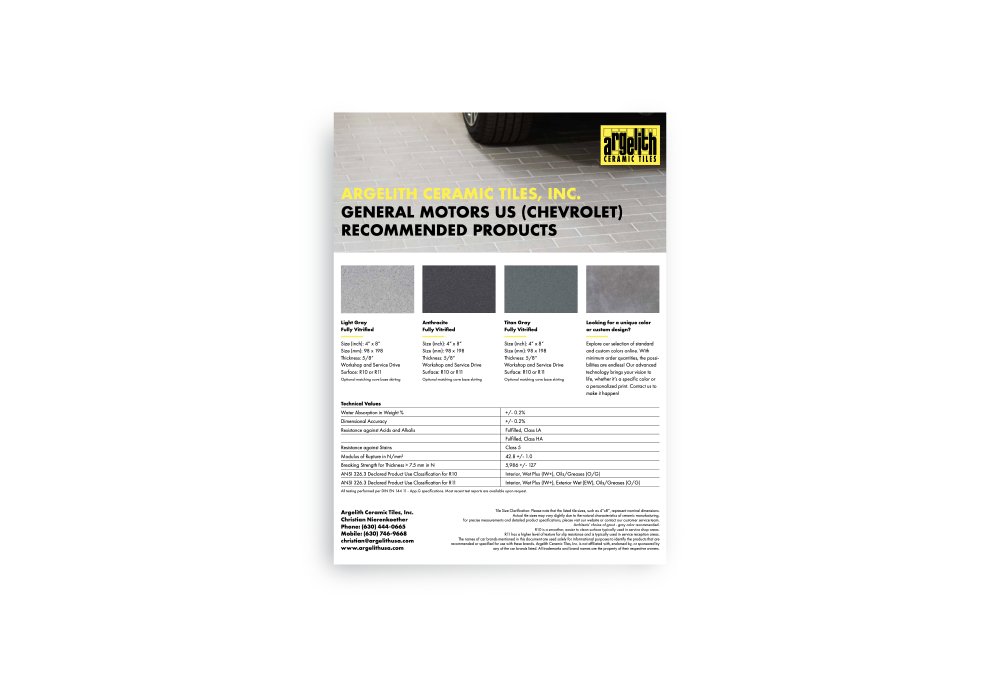

General Motors Us (Chevrolet)

Buick

Maintenance Tips to Ensure Your Floor Lasts

Proper maintenance extends the life and performance of your Argelith flooring. Follow these best practices to protect your investment and maintain a clean, safe environment.

Clean Regularly: Use auto-scrubbers to remove oils and debris. For stubborn grime, aggressive pads are acceptable.

Use Proper Grout: In chemical-heavy areas, grout selection should align with the operational environment. In chemical-intensive industries, such as food processing, epoxy grout is recommended for its superior resistance. However, in automotive workshops, cementitious grouts are often preferred due to exposure to oils and other hydrocarbons. Narrow grout joints (1/16"–1/8") are advised across applications to minimize water pooling and reduce the risk of chipped tile edges.

Avoid Standing Water: While the tile is impervious, water can compromise grout over time. Ensure proper drainage.