Industrial Tiles for Chemical Plants & Laboratories

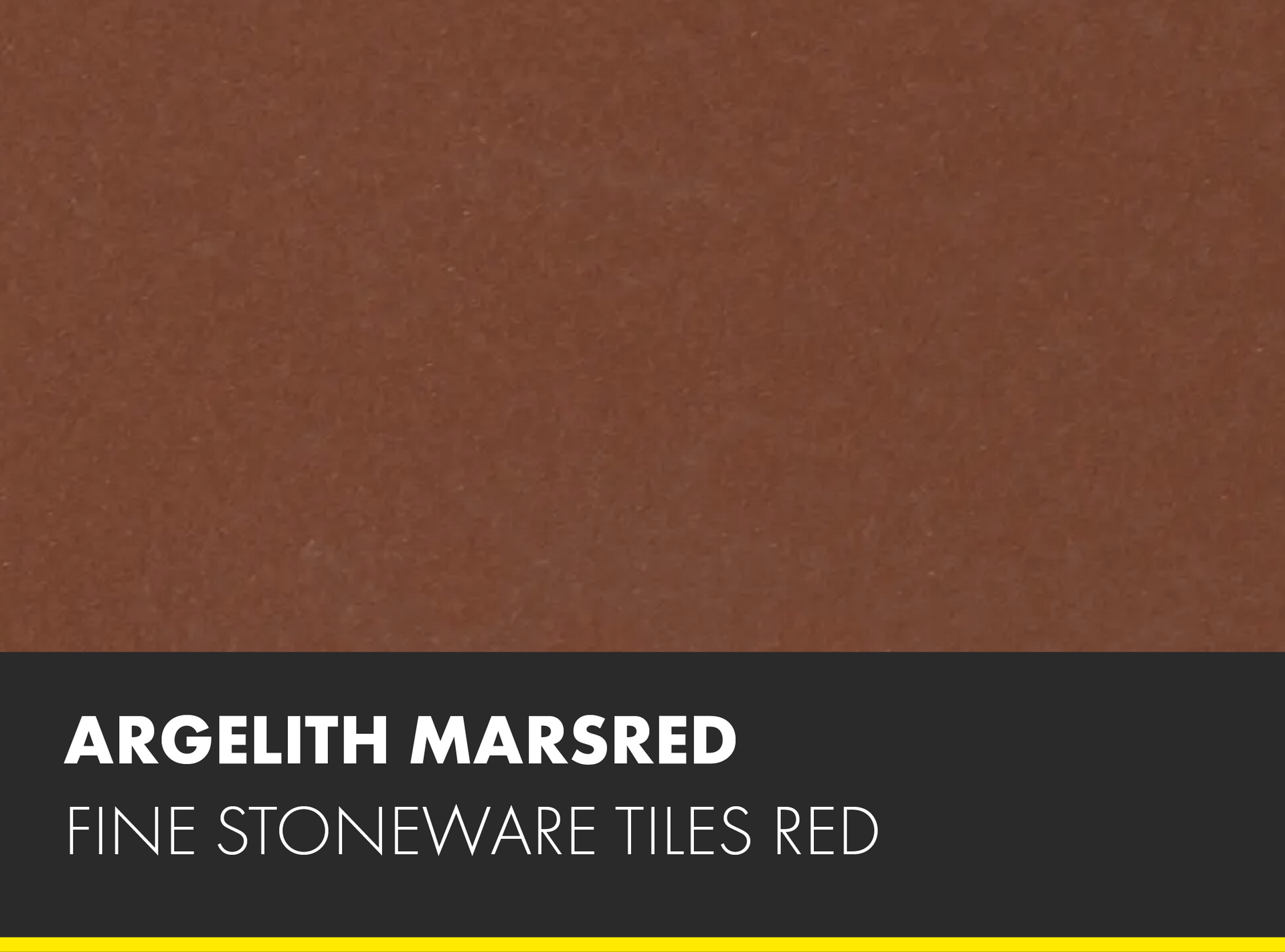

Whether rectangular, square, hexagonal or a ceramic moulding – Argelith offers a wide range of shapes, colours and surfaces in the porcelain stoneware sector. Further details can be found in the following product descriptions.

Argelith engineered tiles deliver specialized performance for chemically intense and hygiene-sensitive spaces.

- Superior Chemical Resistance: Fully vitrified tiles repel corrosive agents, reducing degradation.

- Low Porosity: Non-absorptive surfaces help prevent microbial growth and fluid infiltration.

- Precision Fit: Tight joints and rectified edges support contamination control efforts.

- Hygienic Surface: Withstands disinfectants, steam, and acid washing without surface wear.

- Long-Term Value: High performance reduces the need for repair or early replacement.

Challenges in Chemical Plants & Lab Flooring

Facilities handling chemicals and sensitive materials require flooring systems that meet the highest standards of durability, hygiene, and contamination control. Whether in a laboratory, pharmaceutical plant, or industrial chemical environment, the floor plays a critical role in maintaining safety and operational efficiency.

Chemical Resistance

Exposure to corrosive substances such as acids, alkalis, solvents, and reagents is common in chemical environments. Many flooring materials degrade under these conditions, leading to surface breakdown, safety hazards, and contamination risks. Argelith ceramic tiles are fully vitrified, meaning their nonporous structure resists chemical penetration and prevents deterioration. This integrity is maintained even under repeated exposure, making them an ideal solution for spaces that demand long-term resistance.

Contamination Control

Controlling particulate matter and preventing cross-contamination are essential in labs and clean manufacturing settings. Cracks, porous surfaces, and wide grout lines can harbor contaminants, undermining facility standards. Argelith tiles are manufactured through a dry-press process in precision molds, resulting in consistent dimensions that support narrow grout joints. This minimizes crevices, aiding in the maintenance of cleanroom protocols. Their dense, non-absorptive surface further helps preserve a sterile environment, reducing the risk of product contamination or research compromise.

Need for Hygiene

Hygiene is a top priority in pharmaceutical labs, food-grade chemical plants, and R&D facilities. Flooring must support frequent cleaning and disinfection without losing its surface integrity. Argelith tiles withstand aggressive sanitation protocols, including acidic washes, steam cleaning, and industrial-grade disinfectants. The baked-on finish resists fading and surface erosion, preserving both cleanliness and visual consistency over time.

How Argelith Ceramic Tiles Benefit Chemical Environments

application areas

argelith tiles

Whether in the food industry, vehicle workshops, laboratories and the chemical industry or in rescue centers, heavy-duty floor coverings are required in all of these areas. The special requirements for slip resistance, hygiene and load-bearing capacity can vary greatly. Argelith has specialized in precisely these areas of application and provides the right basis for your industrial flooring with extra-strong tiles in 3/8 to 3/4 inch thickness.

Maintenance Tips to Ensure Your Floor Lasts

Protect your investment and maintain optimal performance with these best practices:

Choose the Right Grout: In chemical environments, epoxy grout is recommended to ensure chemical compatibility and long-term durability. For Clean-in-Place (CIP) systems or areas exposed to extreme chemicals, vinyl ester grout offers superior resistance and should be considered as an alternative.

Implement Routine Cleaning Protocols: Argelith tiles

can handle auto-scrubbers, steam equipment, and high-strength sanitizers.

Monitor for Spill Accumulation: While tiles resist chemical penetration, prompt cleanup prevents grout degradation.

Inspect Critical Zones Regularly: Check high-use and high-exposure areas to address wear before it becomes an issue.

Nothing Yet?

choose your favorite product from our diverse collection

A floor must be resistant if it is to provide a perfect base for handling chemicals of various kinds. It should be impervious to both corrosive and non-corrosive substances, and must be able to withstand anything from high-pressure steam and acid treatments to the action of heavy loads. Here, Argelith offers a wide range of robust ceramic tiles that are highly resilient to both chemical and physical wear. Business organisations such as BASF or Aventis have come to appreciate this quality – with production plants that have been relying on Argelith for many years.