Slip-Resistant Flooring Guide – Prevent Workplace Accidents

The Cost of Workplace Accidents: Slips, Trips, and Falls

Every year, slips, trips, and falls contribute to thousands of workplace injuries and billions in financial losses. According to the National Safety Council, these incidents are among the most common and costly across industrial and commercial environments. Beyond medical expenses and lost productivity, companies face potential regulatory fines and reputational damage.

Why Slip-Resistant Flooring Is Critical for Safety

Slip resistance is a fundamental component of workplace safety and slip, trip, and fall prevention. In industries where wet conditions, heavy traffic, or product spills are common, flooring must be designed to mitigate risk. Choosing the right slip-resistant flooring can significantly reduce the risk of accidents, safeguard employees, and contribute to regulatory compliance.

Understanding Slip, Trip, and Fall Prevention

Slip, trip, and fall incidents typically result from a combination of factors: wet or oily surfaces, uneven flooring, poor drainage, and inadequate cleaning practices. Flooring plays a pivotal role in both the prevention and potential causes of these events.

Key strategies for prevention include:

- Ensuring flooring has an appropriate coefficient of friction (COF) for the environment.

- Designing spaces with drainage and slope to reduce standing water.

- Incorporating safety striping and color contrast for visibility.

- Implementing routine maintenance protocols to remove hazards.

Comprehensive prevention begins with

selecting flooring that is engineered with safety in mind.

What is Slip-Resistant Flooring?

Slip-resistant flooring is designed to maintain traction under various environmental conditions, reducing the likelihood of slips and falls. It is particularly essential in facilities exposed to moisture, oils, or cleaning agents. However, not all slip-resistant surfaces are created equal. Understanding how resistance is measured and maintained is critical to selecting the right flooring solution.

Defining Slip Resistance: Key Metrics and Standards

Slip resistance is most commonly measured using the Coefficient of Friction (COF), which quantifies the amount of grip a surface provides. Higher values indicate greater slip resistance. Standards vary globally, but two key references include:

ANSI A326.3-2021: This is the primary U.S. standard for measuring slip resistance, focusing on the dynamic coefficient of friction (DCOF) of hard surface flooring materials. A DCOF of 0.42 or greater is generally recommended for wet conditions.

DIN 51130 / R Ratings: Widely used in industrial settings, this German standard evaluates surfaces in oily conditions and assigns an R-value (R9–R13) to indicate slip resistance. Argelith tiles are available with R11 and R12 finishes for high-risk environments.

These metrics allow facility managers and safety officers to align flooring specifications with regulatory requirements and actual operational conditions.

Differences Between Textured, Coated, and Engineered Slip Resistance

There are several methods by which slip resistance is achieved, each with its own performance profile:

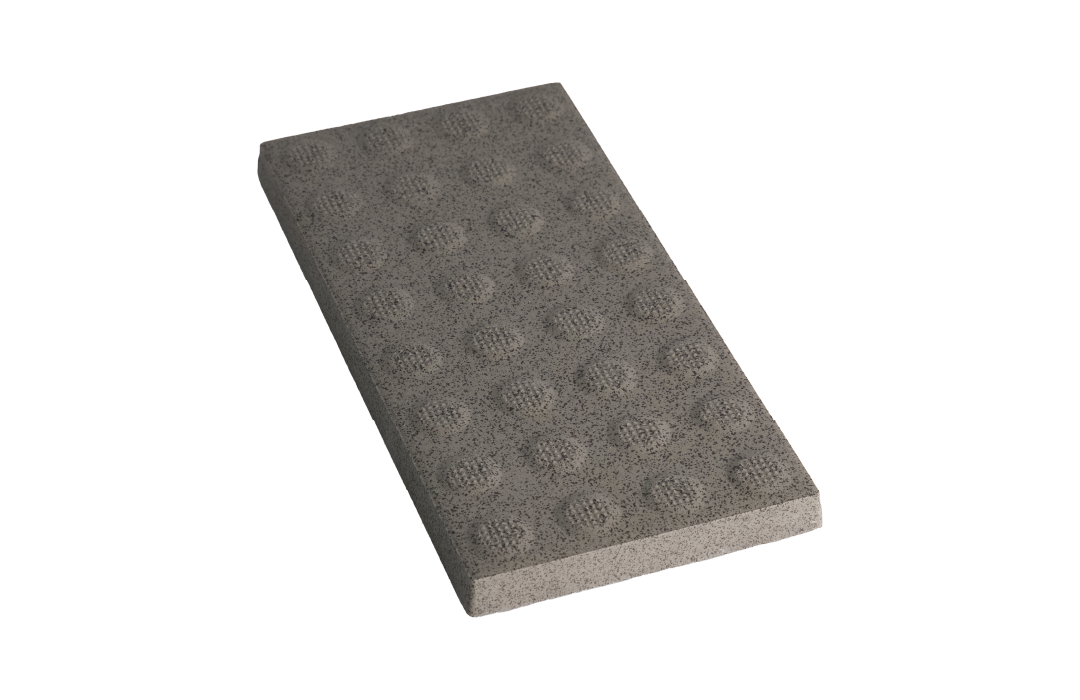

- Textured Surfaces: These feature a permanently rough finish molded or pressed into the tile body. This method, used in Argelith’s tiles, offers consistent performance over time with minimal degradation.

- Coated Finishes: Common in epoxy and resinous flooring systems, these rely on surface treatments or grit additives. While effective initially, they are prone to wear and require frequent recoating.

- Engineered Surface Structures: Some materials are manufactured with embedded granules or micro-patterns designed to optimize friction. These are more durable than coatings but still may degrade under extreme conditions.

Fully vitrified ceramic tiles with baked-in texture provide long-lasting slip resistance, even under aggressive cleaning and mechanical traffic.

There are several methods by which slip resistance is achieved, each with its own performance profile:

- Textured Surfaces: These feature a permanently rough finish molded or pressed into the tile body. This method, used in Argelith’s tiles, offers consistent performance over time with minimal degradation.

- Coated Finishes: Common in epoxy and resinous flooring systems, these rely on surface treatments or grit additives. While effective initially, they are prone to wear and require frequent recoating.

- Engineered Surface Structures: Some materials are manufactured with embedded granules or micro-patterns designed to optimize friction. These are more durable than coatings but still may degrade under extreme conditions.

Fully vitrified ceramic tiles with baked-in texture provide long-lasting slip resistance, even under aggressive cleaning and mechanical traffic.

Factors Affecting Slip Resistance: Contaminants, Wear, and Maintenance

Even the best slip-resistant flooring can underperform without proper care. Several factors impact effectiveness:

- Contaminants: Water, oil, food debris, and chemicals can significantly reduce surface traction if not promptly cleaned.

- Wear: Heavy traffic and mechanical abrasion can smooth out textured or coated surfaces over time.

- Maintenance Practices: Using inappropriate cleaning agents, failing to remove buildup, or neglecting routine care can diminish slip resistance.

Argelith tiles are designed to resist these challenges with a hard, dense surface and robust texture. Routine cleaning with compatible scrubbing systems ensures long-term safety performance.

Flooring Materials Compared

Choosing the right flooring material for slip resistance involves evaluating not just initial traction, but also long-term performance, maintenance needs, and suitability for your operational environment. Here's how common materials stack up.

Common Materials and Their Slip-Resistance Properties

- Epoxy Floors: These can be textured or treated with nonslip aggregates, offering good initial slip resistance. However, they are prone to wear and degradation from thermal shock or aggressive cleaning agents.

- Rubber Flooring: Naturally slip-resistant and comfortable underfoot, rubber is suitable for light-duty environments. However, it can soften or degrade in areas exposed to oils, chemicals, or high heat.

- Polished Concrete: Often selected for its cost efficiency, concrete is a smooth surface that becomes hazardous when wet unless textured or treated. Surface treatments wear off over time, requiring regular reapplication.

- Textile and Vinyl Flooring: In dry, light-traffic areas, these may offer some slip resistance. However, they are typically unsuitable for industrial or wet environments.

- Ceramic Tiles: When fully vitrified and textured, ceramic tiles provide excellent long-term slip resistance, even under demanding conditions.

Each material has a place, but only a few offer a balance of durability, cleanability, and safety required in high-risk zones.

Challenges with Coated Surfaces and Resinous Floors

Surface coatings, like those used in epoxy or resinous systems, depend heavily on the integrity of their top layer. Over time, this coating can wear down or delaminate due to:

- Foot and forklift traffic

- Exposure to harsh chemicals

- Thermal cycling and washdowns

Once compromised, these surfaces often lose their slip-resistant properties, potentially creating new safety hazards. Repairs and re-coatings add to lifecycle costs and downtime. For facilities requiring continuous uptime and consistent safety, this poses a significant risk.

Why Fully Vitrified Ceramic Tiles Offer Lasting Non Skid Performance

Argelith’s fully vitrified ceramic tiles are engineered with a permanent surface texture that doesn’t rely on coatings or treatments. Benefits include:

- Permanence: The textured surface is integral to the tile body, maintaining traction throughout the tile’s life.

- Resistance to wear: High Mohs hardness and compressive strength ensure durability under heavy machinery and abrasive cleaning.

- Low maintenance: No need for recoating or resurfacing—just regular cleaning with an auto-scrubber.

- Certified safety: Tiles meet international standards (e.g., R11 or R12 slip resistance ratings), ensuring regulatory compliance.

These attributes make vitrified ceramic tiles a trusted solution for long-term slip resistance in industrial and commercial settings.

Argelith Ceramic Tiles: Slip-Resistant by Design

Argelith tiles are engineered with safety at the core. These fully vitrified ceramic tiles are designed for high-performance environments where safety is paramount.

Key Slip-Resistance Features:

- Textured Surfaces: Engineered to provide grip even when wet or contaminated with oil.

- R-Rated Finishes: Tested and rated for slip resistance using DIN standards, Argelith tiles are available in multiple R-ratings to match specific environmental needs. Selecting the appropriate R-rating is critical. Higher R-values are recommended for areas with greater slip risks, such as wet or oily environments, while moderate ratings suit drier, less hazardous zones.

- Non-Porous Body: Prevents liquids from penetrating the tile surface, preserving traction and hygiene.

- Durability: Maintains texture and slip resistance even under abrasive conditions, heavy equipment, and frequent cleaning.

Whether in a brewery, food processing plant, or warehouse, Argelith tiles help operations improve safety by providing a reliable, slip-resistant surface.

Designing for Safety

Achieving slip resistance incorporates tile layout-to-transition details, every design element plays a role in promoting safety and minimizing risks.

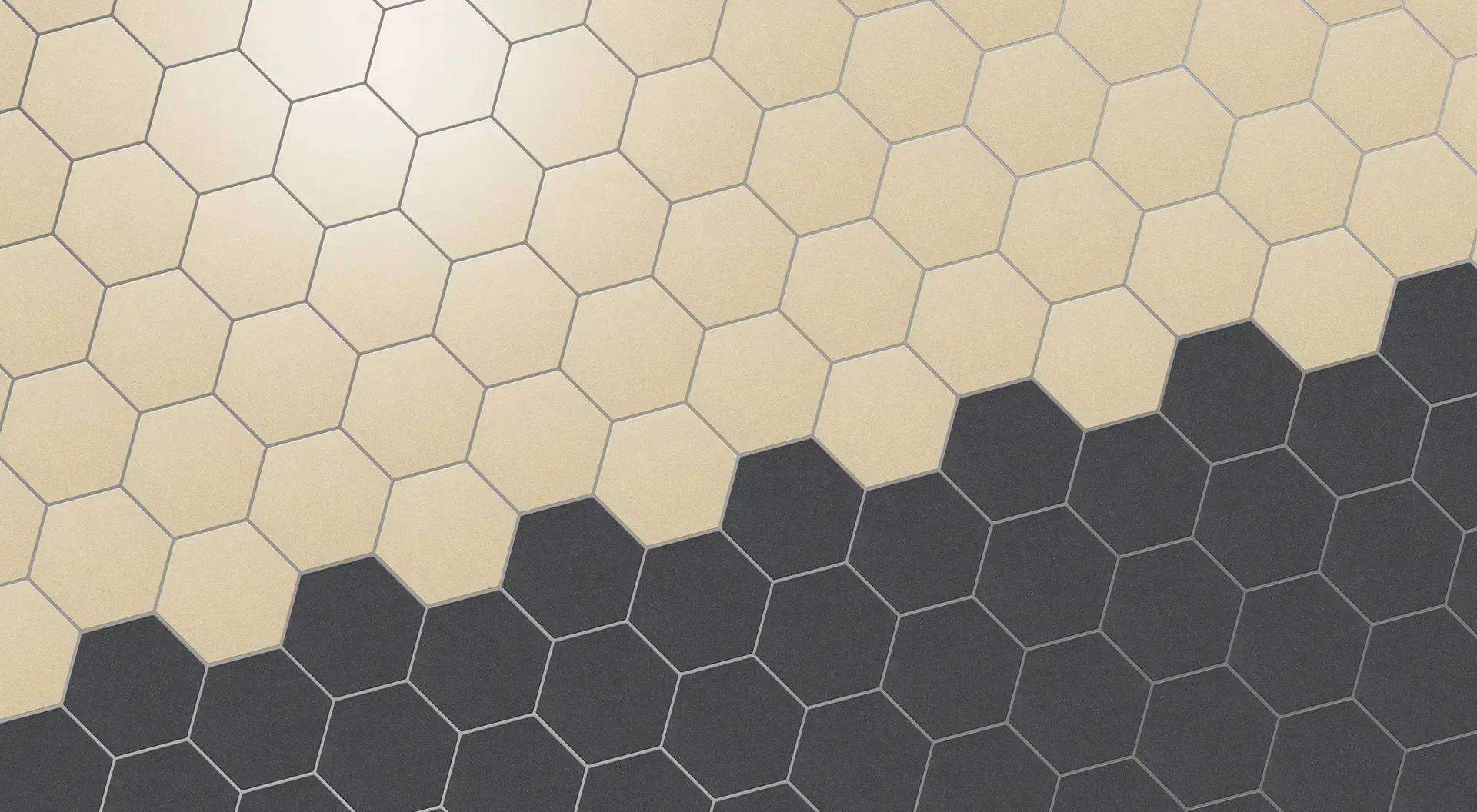

Tile Format and Layout Considerations

Tile size and configuration impact both performance and safety. Smaller formats, such as hexagons or mosaics, are ideal in high-slip-risk areas because they provide more grout lines and natural traction. Larger tiles reduce joints and simplify cleaning, making them suitable for broader traffic areas.

Strategic layout planning can:

- Enhance drainage by aligning joints with slope direction.

- Define zones (e.g., work vs. walk areas) using color or texture variation.

- Improve visibility with contrasting borders or designated safe paths.

Argelith offers a wide range of formats and slip-resistant finishes that allow for both functional and visual zoning.

Narrow Grout Joints to Minimize Trip Hazards

Grout joints may seem minor, but their dimensions significantly influence safety and hygiene. Argelith recommends narrow grout joints between 1/16" and 1/8" for industrial applications.

Benefits include:

- Reduced risk of tripping: Narrow joints create a smoother, more level surface.

- Less water retention: Minimizes puddling and microbial growth.

- Enhanced durability: Prevents edges from chipping under heavy loads or traffic.

In critical areas, epoxy grout should be used for its resistance to chemicals and cleaning agents, helping to maintain joint integrity over time.

Stair Safety and Use of Bullnose Edge Tiles

Stairs present an elevated fall risk if not properly designed. Argelith addresses this with bullnose edge tiles, which provide a rounded transition at the edge of each step, enhancing both safety and visual definition.

Key safety enhancements for stairs include:

- Non-slip surfaces on tread tiles.

- Contrasting colors or edge striping for visibility.

- Uniform riser heights to prevent missteps.

By combining textured finishes with safety-specific tile formats, Argelith supports comprehensive stair safety planning that meets both OSHA guidelines and real-world use cases.

Installation and Maintenance Essentials

Proper installation is essential to achieving the desired slip-resistance. Critical factors include:

- Correct slope for drainage.

- Flush transitions between tile surfaces and adjacent flooring.

- Use of textured or epoxy grout in washdown areas.

- Tight grout joints (1/16"–1/8") to reduce tripping hazards and simplify cleaning.

Post-installation, slip resistance must be preserved through:

- Routine cleaning with auto-scrubbers and compatible detergents.

- Periodic friction testing to monitor COF over time.

Aggressive scrubbing pads can be used when necessary without damaging Argelith’s hard surface finish.

Real-World Applications

Argelith’s slip-resistant tiles are trusted by global leaders in multiple industries around the world.

Why Argelith is the Right Partner

Argelith combines precision German engineering with decades of industry experience to deliver flooring solutions that meet real-world safety challenges.

What Sets Argelith Apart:

- Engineered for performance: Every tile is designed to meet specific technical and safety criteria.

- Wide format and surface options: Available in multiple textures and finishes to suit your slip-resistance requirements.

- U.S.-based logistics: Short lead times and local support for American projects.

- Installation support: Guidance on best practices to ensure long-term safety and compliance.

Argelith’s slip-resistant tiles provide a proven solution for reducing workplace accidents and enhancing safety in both new construction projects and facility upgrades.

Note: Slip resistance depends on proper cleaning, footwear, maintenance, and environmental factors. While Argelith tiles feature engineered textures, no flooring system can eliminate all risk of slips or falls.

Disclaimer: The information in this article is intended as general guidance only and does not replace proper safety planning, professional installation, or maintenance procedures. Slip resistance depends on factors including environment, cleaning regimen, footwear, and installation quality. Argelith does not warrant or guarantee the prevention of accidents. For specific recommendations, please consult with your installer or safety consultant.